PhD defence of Marion Négrier

13 December 2023

Marion Négrier defends her PhD in Computational Mechanics and Materials on Dec. 13, 23.

From textile waste to cellulose aerogels for controlled release applications.

Marion Négrier carried out her PhD research work under the supervision of Tatiana Budtova (BIO team), Elise El Ahmar and Romain Sescousse (IMT Mines Albi). She will defend her doctoral thesis in the Computational Mechanics and Materials speciality on December 13, 2023 in front of the following jury:

M. Pedro FARDIM, Faculty of Engineering Science – KU Leuven, Reviewer

M. Henrikki LIIMATAINEN, Faculty of Technology – University of Oulu, Reviewer

M. Michael HUMMEL, Department of Bioproducts and Biosystems – Aalto University, Examiner

Mme Tatiana BUDTOVA, Centre de Mise en Forme des Matériaux – Mines Paris PSL, Examiner

Mme Elise EL AHMAR, Centre Thermodynamique des Procédés – Mines Paris PSL, Examiner

M. Romain SESCOUSSE, Centre RAPSODEE – IMT Mines Albi Examiner

M. Martial SAUCEAU, Centre RAPSODEE – IMT Mines Albi Guest

Abstract:

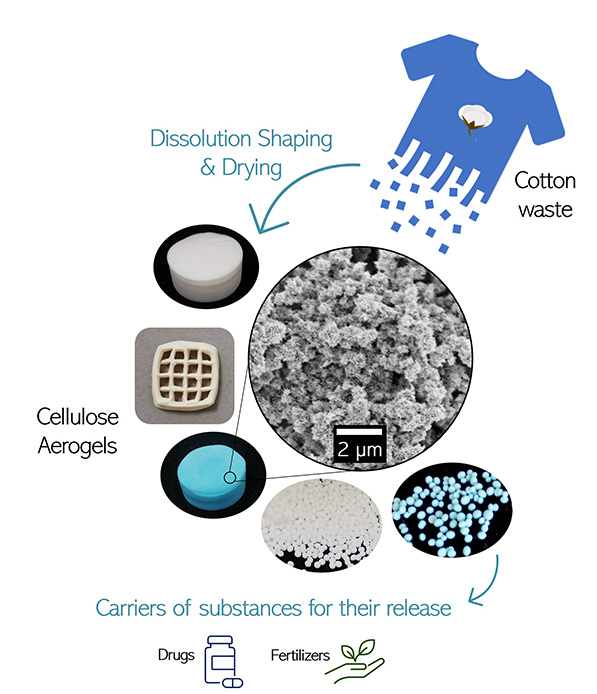

This thesis is devoted to the development of high added value porous materials, cellulose aerogels, from textile waste.

The first chapter provides the state of the art on cellulose structure and dissolution, shaping (prilling, additive manufacturing) and preparation of cellulose aerogels. Different options of cellulose-based textile recycling are overviewed.

The second chapter presents the materials (cellulose from different textiles (viscose, rayon, cotton), solvents (different ionic liquids), non-solvents, etc.) and methods used in the work. The manufacturing and characterization methods of aero-, cryo- and xerogels made from cellulose-based textiles, and also from neat cellulose are detailed. The approaches used to study drug release from cellulose aerogels and their cytotoxicity tests are presented.

The third chapter describes the processes for obtaining aero-, cryo- and xerogels from different cellulosic textiles and studies the properties of the materials obtained depending on the type of cellulose, the molecular weight, the type of solvent, and the methods of coagulation and drying. Textiles are dissolved in ionic liquids: 1-ethyl-3-methylimidazolium acetate ([EMIM][OAc]) or 1,5-diazabicyclo[4.3.0]non-5-ene acetate ([DBNH][OAc]), each mixed 50/50 with DMSO. Aerogels showed a density from 0.07 to 0.2 g.cm−3 and a specific surface area from 320 to 400 m².g−1 with a bead-like inner morphology. Cryogels possessed a density from 0.06 to 0.13 g.cm−3 and a specific surface area from 10 to 100 m².g−1. Xerogels had a density from 0.4 to 1.3 g.cm−3 and a negligible specific surface area. A process to replace supercritical drying resulted in xerogels with a specific surface area around 150 m².g−1.

The fourth chapter highlights the production of cellulose aerogel beads by prilling. This technique is based on the breaking of a laminar jet of a liquid by vibration and leading to the production of spherical droplets which can then be “solidified”. Solutions of microcrystalline cellulose and viscose-based textile were used, and processing parameters were optimized to obtain the more spherical beads with a narrow size distribution. Nozzle diameters of 300 and 400 µm showed best results with a vibration frequency at 100 Hz, a coagulation bath height at 3.5 cm, while the bath temperature did not show any significant impact on the beads’ dimensions. High roundness with a low aspect ratio were obtained with these operating conditions. Aerogel beads showed a density around 0.1 g.cm-3 and a high specific surface area around 400 m².g-1. 3D printing of microcrystalline cellulose-[DBNH][OAc]/DMSO solutions is also presented. Different options of shape stabilization of a printed material were tested. First, the viscosity of the cellulose solution was increased. Then, it was found that the addition of water to cellulose solution and its aging makes them shear-thinning yield stress fluid, suitable for 3D-printing. Precursors were printed, coagulated with ethanol and then dried with supercritical CO2, leading to the 3D-printed aerogels.

Finally, the last chapter presents drug release from aerogels and cryogels based on microcrystalline cellulose dissolved in [DBNH][OAc]/DMSO. Ascorbic acid 2-phosphate was used as model drug. The properties and morphology of aerogels and cryogels are modified by varying the manufacturing process. The drug release kinetics is monitored using UV-vis spectrophotometer and approaches used to model release kinetics applied. Finally, cytotoxicity tests are carried out on the solvent as well as on the aerogels; the results demonstrated that aerogels are harmless as tested on in vitro cell cultures.

Keywords: biomaterials, textile, bio-aerogel, cellulose