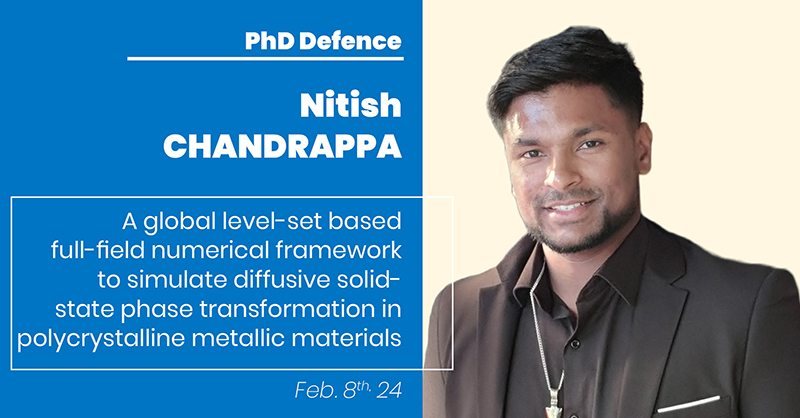

PhD defence of Nithish Chnadrappa

Nitish Chandrappa defends his PhD in Computational Mechanics and Materials on Feb. 8th, 2024.

A global level-set based full-field numerical framework to simulate diffusive solid-state phase transformation in polycrystalline metallic materials

Nitish Chandrappa conducted his PhD work in the MSR team under the supervision of Marc Bernacki. He will defend his thesis in front of the following jury:

– BRUCHON Julien, MINES Saint-Etienne, IMT, France École des Mines de Saint-Étienne Centre SMS

– MADEJ Lukasz, AGH University, Poland AGH University of Krakow WIMiIP

– KRILL III Carl, Ulm University, Germany

– CHARBONNIER Nicolas, ArcelorMittal

– BIGNON Madeleine, MINES Paris, France

– DE MICHELI Pascal, Transvalor SA, France

– BLAIZOT Jérôme, Aubert & Duval, France R&D

Abstract:

The underlying fabric of materials adapts in response to external stimuli. This adaptability manifests through microstructural transformations that can significantly impact the material’s performance, emphasizing the importance of understanding and predicting microstructural evolution. Integrating numerical modeling is pivotal for gaining deeper insights into these complex phenomena. Digitizing material engineering processes is the driving force behind shaping the materials of tomorrow. Recent progress in computational resources has spurred a demand for mesoscopic numerical models, offering realistic descriptions of evolutionary aspects. During hot metal forming involving high plastic deformation, the evolution of metallic alloys experiences a complex interplay of multiple simultaneous phenomena that shape their microstructure. Currently, cutting-edge numerical predictions emphasize single-phase microstructural changes or isolate phase transformations, often neglecting contributions from other coexisting phenomena. This narrow focus could impede a holistic understanding of microstructural evolution. A level-set-based full-field numerical formulation featuring a generalized kinetic framework tailored for two-phase metallic polycrystals is thus proposed in this work. This inclusive kinetic framework is capable of proficiently accommodating multiple microstructural transformations, including diffusive solid-state phase transformation, recrystallization, and grain growth. The level-set method proves effective in simulating recrystallization and grain growth under high plastic deformation. However, its potential in addressing diffusive phase transformation in the solid-state has not been extensively investigated. The primary focus of this work is thus to simulate diffusive solid-state phase transformation in metallic polycrystals using the proposed numerical framework to explore the potential of level-set method in this context. The numerical model is demonstrated to effectively reproduce expected physical characteristics, particularly emphasizing austenite decomposition in steels. The proposed level-set numerical model is benchmarked against a state-of-the-art sharp interface semi-analytical model. The potential of the proposed numerical framework to replicate the phase transformation behavior in complex polycrystalline microstructures is showcased. The versatility of the framework to integrate other complex evolution is highlighted.

Microstructural evolution during diffusive phase transformation from gamma phase to alpha phase

Keywords: FE Method, Diffusive phase transformation, Austenite Decomposition, Metallurgy, Microstructure evolution, Level-set