Metallurgy, microStructure, Rheology – MSR_old

PERMANENT MEMBERS

Marc Bernacki (Head)

Charbel Moussa

Cyrille Collin

Gilbert Fiorucci

Alexis Nicolaÿ

Baptiste Flipon

Madeleine Bignon

Oriane Senninger

Karim Inal

Daniel Pino Muñoz

Research Field

Microstructure evolutions of alloys during thermomechanical processing (in the solid state).

Applications

- Hot and cold forming, high strains

- Thermal treatments

- Recrystallization, grain growth, phase transformations

- Nickel-based superalloys, titanium alloys, aluminum alloys, steels,…

Main objectives

MSR team works on microstructure evolutions induced by thermomechanical processing of metallic materials in the solid state. The research mainly focusses on the :

- description of active physical mechanisms and their kinetics as a function of thermomechanical parameters at the mesoscopic level,

- formulation of physical models describing plastic deformation, recrystallization, grain growth, phase transformations and their couplings,

- implementation of these models in predictive tools for the simulation of microstructural evolutions. This domain implies the development of new numerical methods (HPC in computational metallurgy and mechanics, meshing/remeshing tools, front-tracking and front-capturing description of polycrystalline materials) for high-fidelity simulations but also the development of multiscale modeling strategies and the development of surrogate models through machine learning strategies (e.g. in RealIMotion ANR industrial chair).

Originality of the developed approach lies in the combination of skills and complementary tools: experimental physical metallurgy, mechanical metallurgy, modeling and numerical simulation to address/handle cases, which are complex in nature, close to industrial operations. These works are realized through close collaboration between experimental and numerical analyses.

The MSR team also manages and develops experimental methodologies: thermomechanical tests and heat treatment of metallic materials, metallography and electron microscopy.

Research areas

- Development of experimental tools and methods for quantitative microstructure analysis

- Identification of metallurgical mechanisms and their kinetics

- Mean field modeling and simulation

- Full field modeling and simulation

- Development of numerical methods

- Development of numerical methods

- Multiscale modelling and low-oder surrogate models development thanks to ML strategies

- Development of libraries and calculation codes: cimlib, DIGIMU, Fitz, MPCP, ToRealMotion (TRM), MDivide, DYNAMIX

Current Projects

RealIMotion ANR industrial chair

Work program: 7 PhD theses over the period 2022 – 2026.

Holder: Marc Bernacki, Deputy: Nathalie Bozzolo.

Objective: Data science, physical models enhancement and machine learning at the service of industrial digital metallurgy.

Co-funded by ANR - ArcelorMittal, Framatome, Aperam, Aubert&Duval, CEA, Safran, Constellium. Transvalor non-funding partner.

Learn more

TOPAZE ANR-SAFRAN INDUSTRIAL CHAIR

Work program: 8 PhD theses over the period 2020 – 2024.

Holder: Nathalie Bozzolo, Deputy: P. Villechaise (Pprime institute).

Objective: Controlling forged microstructures in order to optimize the service life of polycrystalline nickel-based superalloys in new generation aircraft engines and helicopter engines: Focus on 𝛾-𝛾 'alloys.

In collaboration with Pprime institute to understand/study microstructure-property relationships.

Co-funded by ANR - Safran.

Learn more

DIGI𝝁 ANR INDUSTRIAL CHAIR

Work program: 6 PhD theses over the period 2016 – 2020.

Holder: Marc Bernacki, Deputy: Nathalie Bozzolo.

Objective: Development of software (DIGIMU®) usable in an industrial environment for full field simulation of recrystallization phenomena.

Co-funded by ANR – ArcelorMittal, Framatome, Ascometal, Aubert&Duval, CEA, Safran.

With additional participation of Constellium, Timet and Transvalor.

Learn more

CONTiNUUM project

Work program: 6 PhD theses over the period 2019 – 2025.

Head: Nathalie Bozzolo.

Objective: Describing microstructure and crystallographic texture evolutions during forging operations and their impact on properties of titanium alloys for aeronautical applications at high temperature.

In collaboration with Pprime institute and Chimie ParisTech

Co-funded by Airbus - Safran - Aubert&Duval - Timet.

OPALE ANR-SAFRAN INDUSTRIAL CHAIR

Work program: 12 PhD theses and 3 post-docs over the period 2015 – 2020.

Holder: Nathalie Bozzolo, Deputy: P. Villechaise (Pprime institute).

Objective: Optimization of polycrystalline nickel-based superalloys properties by controlling the microstructure resulting from forging operations.

In collaboration with Pprime Institute to study microstructure-property relationships.

Co-funded by ANR - Safran.

Learn more

Equipments

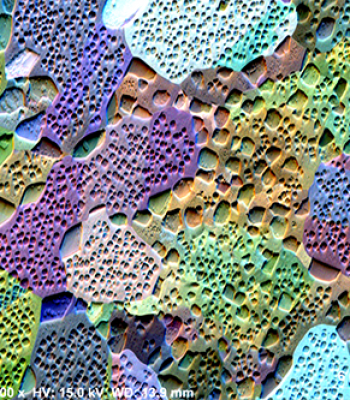

- Dual beam microscope equipped with EDS and EBSD analysis systems for the analysis of microstructures in three dimensions. This microscope is also equipped with a heat treatment chamber with controlled atmosphere.

- High spatial resolution scanning electron microscope (FEG) equipped with combined EDS/EBSD analysis.

- Thermal and thermomechanical treatments up to 1200°C with possibility of water quenching.

MSR TEAM Highlights :

Three ANR industrial chairs and one common laboratory

About thirty ANR industrial chairs in all fields have been selected for funding by the ANR since their creation in 2011. Three of these chairs concern the field of metallurgy and are carried out by the MSR team: OPALE, DIGIMU and TOPAZE, selected from project proposals in 2014, 2016 and 2019 respectively. In 2019, the OPALE common laboratory was also created with Safran.

Tracking of microstructure evolutions during thermal treatments thanks to a in-situ heating stage

Orientation maps resulting from EBSD analyses performed after successive thermal treatments on an aluminum alloy. These tests were carried out in the frame of the PhD thesis work of Saoussen OUHIBA, PhD student in the MSR team.

3D full field simulation of microstructural evolutions

Grain growth phenomenon during thermal treatment of a nickel-based superalloy (Inconel 718) in presence of second phase particles. This numerical simulation comes from PhD thesis work of Benjamin Sholtes, former PhD student in the MSR team (2014-2017).

First full-field Grain growth modeling thanks to a machine learning strategy

Inco718 subsolvus thermal treatment, first 36 minutes are the input of the surrogate model, the next 24 minutes are fully and correctly predict by the trained model in few seconds (right side to be compared to the exact solution in the left side), Phd of P. Tep, RealIMotion ANR Industrial Chair 2024.

My thesis concerns a nickel-base superalloy used for the manufacture of turbine disks produced by the SAFRAN group. I reproduce experimentally the forming conditions of these disks to understand the associated microstructural developments.

Théo HUYGHE, PhD student in the MSR team

Academic partners :

- Carnegie Mellon University - Pittsburgh, USA

- Chimie ParisTech - Paris, France

- CINaM - Marseille, France

- CONICET - Rosario, Argentina

- EPFL - Neuchâtel, Switzerland

- Institut Pprime - Poitiers, France

- Max Plank Institute - Düsseldorf, Germany

Industrial partners :

- Airbus

- ArcelorMittal

- Ascometal

- Aubert&Duval

- CEA

- Constellium

- Framatome

- Timet

- Safran

- VDM Metals International

MSR team keywords :

Physical, mechanical and numerical metallurgy

High strains, Complex thermomechanical paths

Recrystallization, Grain Growth, Precipitation, Phase Transformation

Experimental analysis, HPC in computational metallurgy, meshing and remeshing tools, Multiscale modeling, front-capturing approaches (level-set, multiphase field), front-tracking (Vertex, CA and MC), surrogate models based on machine learning strategy, elastodynamic.

Electron microscopy, EBSD

2D/3D Microstructures

Superalloys, Titanium Alloys

On going PhD projectS

- Lahcen ABARAY : Modeling of continuous dynamic recrystallization (CDRX). MNM specialty, Class of 2023

- Mekki GADDACHA : 3D crack propagation in a CMO/CMO interface at mesoscopic scale. MNM specialty, Class of 2023

- Tianchi LI : New insights in the reduced mobility description for the modeling of grain growth and recrystallization at the Polycrystalline scale. MathNum specialty, Class of 2023

- Fernando PASCUAL GOCE : Microstructure evolution during forging of the VDM® Alloy 780 : Mean field modeling of subsolvus recrystallization and effect of chemical composition onkinetics. MNM specialty, Class of 2023

- Ladji Bafétégué OUATTARA : Bio-sourced circuit printed by new electro-printing methods. MNM specialty, Class of 2023

- Corentin STRADY : Grain growth mechanisms and kinetics in a nickel-based superalloy developed by powder metallurgy for new generation turbine disks. MNM specialty, Class of 2023

- Pungponghavoan TEP : AI and digital twins in metallurgy – Front-tracking modeling of evolving interface networks. MathNum specialty, Class of 2023

- Eliane YOUNES : Artificial Intelligence and digital twins in metallurgy – Front-tracking modeling of evolving interface networks. MathNum specialty, Class of 2023 + CFL team

- Pauline HAHN : Metallurgical evolution of Zr-Nb alloys during hot deformation processes: mechanisms understanding and simulations. MNM specialty, Class of 2022

- Théo HUYGHE : Ring rolling impact on the microstructure of new generation turbine disk. MNM specialty, Class of 2022

- Federico ORLACCHIO : Prediction of changes in the microstructure of gamma/gamma’ alloys during the shaping of turbine disks for new generation engines. MNM specialty, Class of 2021

- Antonio POTENCIANO CARPINTERO : Heterogeneous grain growth in the iron base superalloy 286. MNM specialty, Class of 2021

- Adrien TALATIZI : Simulation of wave propagation in highly heterogeneous media. MathNum specialty, Class of 2021

- Franco JAIME : Microstructure of nickel-based superalloys: Experimental analysis and 3D numerical simulation. MNM specialty, Class of 2020