Theme: Research

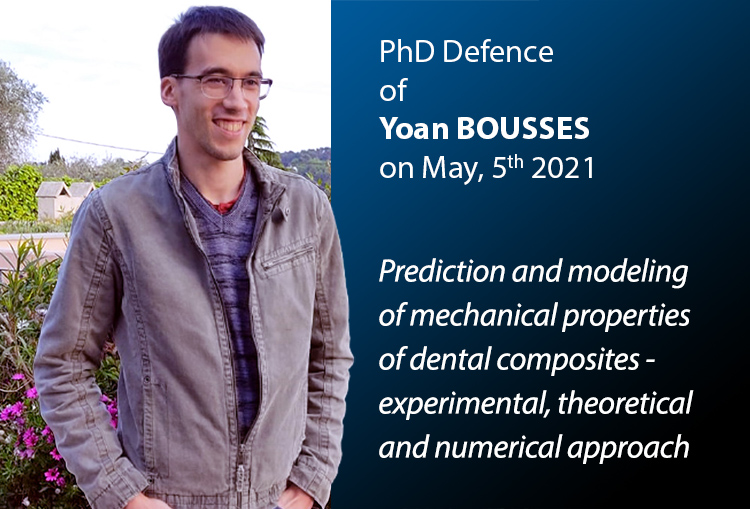

PhD defence of Yoan Boussès

Yoan Boussès defends his PhD in Numerical Mechanics and Materials on May 5th, 2021

Prediction and modeling of mechanical properties of dental composites – experimental, theoretical and numerical approach

Yoan Boussès conducted his PhD work in CSM team, under the supervision of Yannick Tillier, CEMEF and Nathalie Brulat, Associate Researcher, Unviersity Côte d'Azur, Dental Chirurgy Faculty. The project was financed in the framework of the ANR Toothbox Project by ARMINES. He defends his PhD in Numerical Mechanics and Materials on May 5, 2021 in front of the following juy:

- Pr. Brigitte GROSGOGEAT (Univ. Lyon 1 LMI-Univ. Claude Bernard, Villeurbanne) : rapporteur

- Pr. Daniel RITTEL (Inst. de Technologie d'Israël, Haifa, Israël) : rapporteur

- Pr. Pierre COLON (Université de Paris, Paris) : examinateur

- Pr. Piere-Olivier BOUCHARD (MINES ParisTech-CEMEF, Sophia Antipolis) : examinateur

Abstract:

As tooth decays are the most widespread pathologies, dental restoration is a global public health problem. Manufacturers of dental composite resins must therefore offer increasingly high performance and lasting materials while meeting health recommendations. The development process is costly but could be improved by a better understanding of their mechanical behaviour and the development of theoretical and numerical predictive models for their properties.

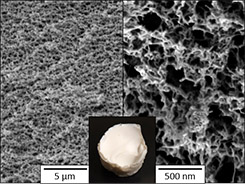

In this work, an experimental material is tested before and after accelerated ageing protocols (thermocycling). A detailed experimental protocol has been established so that the results are reproducible and comparable between them. Predictive models of the yield stress and the elastic modulus, initially proposed for other applicaions, are compared with experimental results and then adapted to the specificities of dental composites, with high filler ratios. The use of a numerical model of a composite material also makes it possible to enrich the experimental database by playing for instance on the modulus of the components, without having to produce the materials. Despite some limits of the innovative approach, the comparison of experimental, theorical and numerical results gives promising outlooks. They allow to predict essential characteristics of composites in an easier way and to make direct connections between macroscopic and microscopic properties. Finally the understanding of the ageing mechanisms was improved.

Keywords: Mechanical characterization of dental composites, Thermocycling, Interfaces, Numerical modelling, Elastic properties

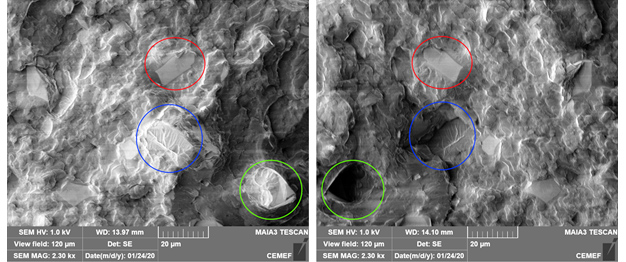

MEB pictures of the two fracture surfaces of a broken composite sample. Broken particles are highlighted in red and debonded particles in green and blue.

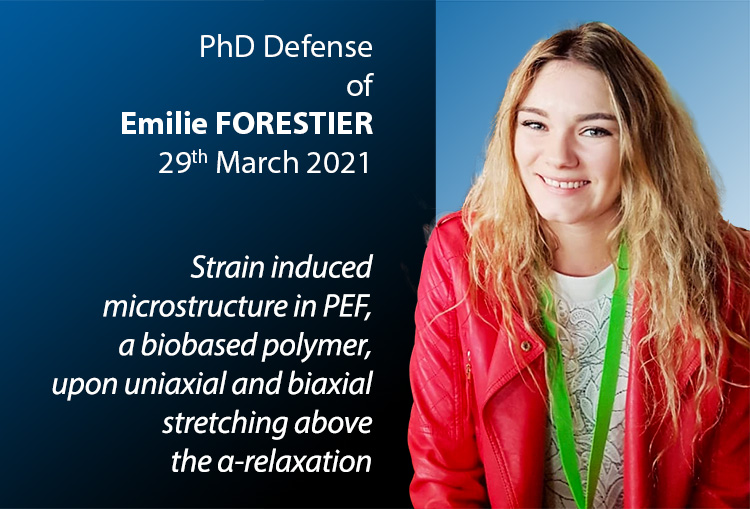

PhD Defense of Emilie Forestier

Emilie Forestier defends her PhD in Numerical Mechanics and Materials on March 29, 21

"Strain induced microstructure in PEF, a biobased polymer, upon uniaxial and biaxial stretching above the α-relaxation"

Abstract:

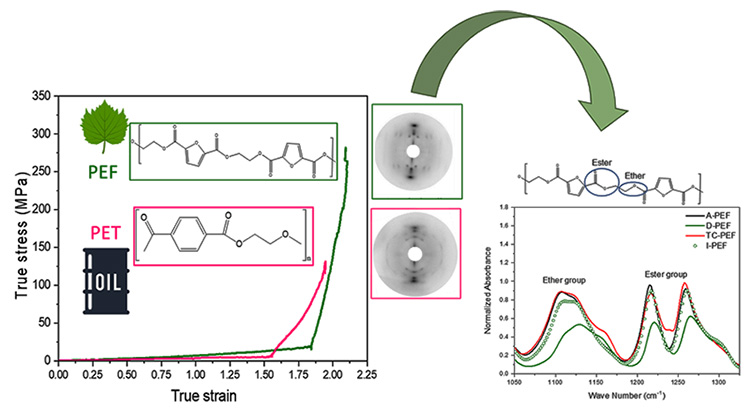

Uniaxial stretching of PEF (biosourced material) and PET. Influence of stretching on the aliphatic part of the chain

Keywords: Strain induced crystallization, uniaxial and biaxial stretching, biobased polymer, microstructural analysis, PEF, thermomechanical behaviour

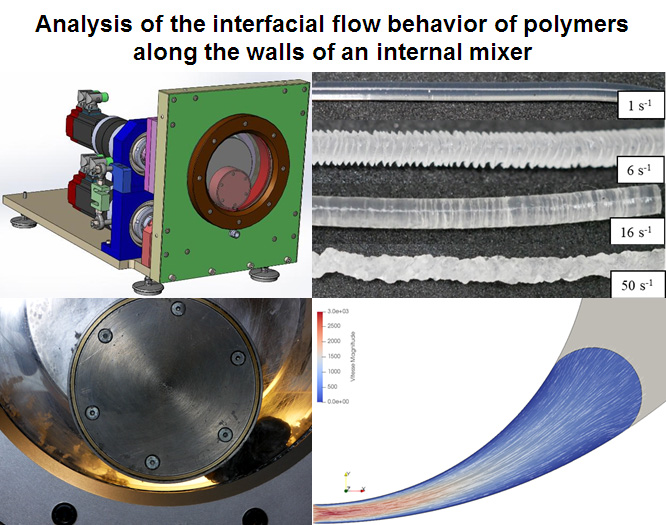

PhD defence Prashanth Thirunavukkarasu

Prashanth Thirunavukkarasu defends his PhD in Numerical Mechanics and Materials on March 31, 21

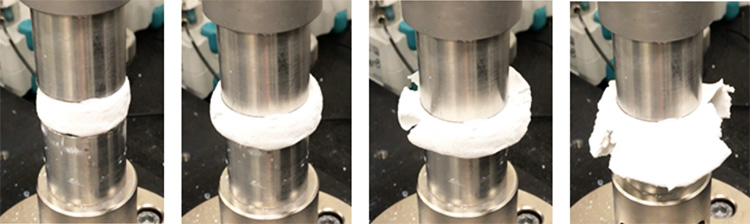

PhD Defense of Pierre-François Mougard-Camacho

Pierre-François Mougard-Camacho defends his PhD in Numerical Mechanics and Materials on March 8, 21

PhD defense of Malik Durand

Malik Durand defends his PhD in Numerical Mechanics and Materials on Jan. 18, 2021

Metallurgical mechanisms upon stress relaxation annealing of the AD730TM superalloy

Malik Durand conducted his PhD work in MSR team, under the supervision of Nathalie Bozzolo in the framework of Industrial Chair ANR SAFRAN OPALE. He defends his PhD in Numerical Mechanics and Materials on January 18, 2021 in front of the following juy:

Coraline Chartier research awarded at the EPNOE IJM

Coraline Chartier is a 2nd year doctoral student in the BIO team at CEMEF. She has just received the Best Poster Award at the Virtual Conference organised by the EPNOE association. The 4th EPNOE Junior Scientist Meeting took place on 3 and 4 February 2021. Among the 38 posters presented, the jury rewarded three young researchers, including Coraline Chartier.

Coraline Chatier works on chitosan aerogel and more precisely on the influence of processing conditions on chitosan aerogel structure and properties.

Her objective focuses on biomedical applications, and solutions for wound healing, tissue engineering or controlled drug release.

Coraline is doing her PhD work at CEMEF with Tatiana Budtova, in the framework of a project funded by the CNRS.

>> More details on the Conference site

>> To know more about the work of BIO Team