PhD Defense of Emilie Forestier

29 March 2021

Emilie Forestier defends her PhD in Numerical Mechanics and Materials on March 29, 21

"Strain induced microstructure in PEF, a biobased polymer, upon uniaxial and biaxial stretching above the α-relaxation"

Emilie Forestier completed her thesis within the MPI team, under the direction of Noëlle Billon in collaboration with Nicolas Sbirrazzuoli, Professor at the University of the Côte d'Azur, Institute of Chemistry. Her thesis was funded by Adème.

Her jury is composed of the following personalities:

– Pr.U. Valérie GAUCHER (Univ. Lile-Unité Mat. et Transformations, Cité Scientifique, Villeneuve d'Ascq)

– Pr.U. Isabelle ROYAUD (Univ. de Lorraine-Inst. Jean Lamour, Nancy)

– D.R. Sylvain CAILLOL (Ecole Nat. Sup. de chimie de Montpellier-Inst. Charles Gerhardt, Montpellier)

– Pr.U. Allison SAITER (Univ. de Rouen Groupe Physique des mat.-EIRCAP,St Etienne du Rouvray)

– I.R. Christelle COMBEAUD (MINES ParisTech-CEMEF, Sophia Antipolis)

– M.C. Nathanaël GUIGO (Univ. Côte d'Azur- Inst. de Chimie de Nice, Nice)

– Pr.U. Nicolas SBIRRAZZUOLI (Univ. Côte d'Azur- Inst. de Chimie de Nice, Nice)

– I.R. Roy VISSER (Avantium Zekeringstraat, Amsterdam, Pays-Bas)

– Ing. Mikaël DERRIEN (Sidel, Octeville-sur-Mer)

Abstract:

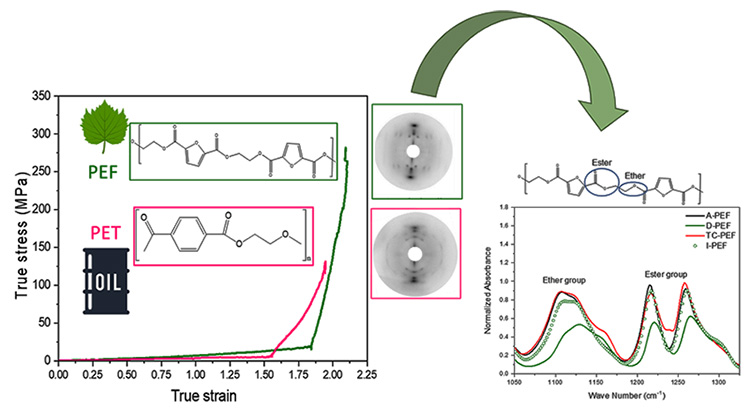

The aim of this work is to provide a better understanding of the mechanical behaviour as well as of the associated microstructural development of a biobased polymer, named PEF. Indeed, this polymer is more and more evocated to replace one of the polymer used in food packaging, PET. PEF is identified as the biobased counterpart of PET. The difference between these two materials is the presence of a furan ring (composed of an oxygen atom with two non-binding electrons), instead of a benzene one, in PEF. This PEF specificity is responsible of a higher glass transition temperature and elastic modulus, a slower crystallization rate, a lower stability of the crystal and a lower melting temperature in comparison with PET.

Based on the stretching of amorphous PET and on its microstructural development, the stretching of amorphous PEF is investigated. Considering the differences in the chain architecture, it appears that PEF and PET cannot be stretched with the same process parameters (strain rate and temperature). In order to perform efficient PEF uniaxial and biaxial tests, it is necessary to define the forming range and some suitable stretching parameters. In this way, a specific stretching protocol, based on the building and on the reading of a master curve at a reference temperature for each material, has been defined and applied on PEF and PET. This master curve allows to know the initial physical state of the material in relation with the couples strain rate/temperature. The stretching mastering and the use of optimize stretching settings lead to the creation of a crystal that increases the thermal stability as well as the rigidity of the material. The mechanical behaviour of PEF reveals that, after the optimization of the stretching settings, this material acts in a similar way as PET. In the first stages of the stretching, both materials mechanical responses are really close. A major difference exists between PEF and PET concerning the apparition of the crystal upon stretching. Indeed, it is found that PEF must form the crystal to strain harden. Up to the end of the stretching, this crystal does not evolve. On the contrary, PET forms firstly a mesophase. The crystal existence is dependent on the final strain and on the quenching protocol.

The microstructure induced upon stretching has been widely analysed and compared to the microstructure existing when a sample is crystallised in static conditions. A high similarity exists between the two ways of crystallization, especially for the crystal definition. It seems that the microstructure induced during the stretching is more constrained than the one obtained from a static crystallization. It has to be noted that the aliphatic part of the chain is the first one impacted by the stretching. This work has also highlighted that the microstructure induced in PEF under stretching is relatively close whatever the stretching conditions are. Concerning PET, the microstructural development seems to be more dependent on the stretching settings.

Uniaxial stretching of PEF (biosourced material) and PET. Influence of stretching on the aliphatic part of the chain

Keywords: Strain induced crystallization, uniaxial and biaxial stretching, biobased polymer, microstructural analysis, PEF, thermomechanical behaviour