PhD Defence of Shitij Arora

16 November 2020

Shitij Arora defends his PhD in Numerical Mechanics and Marerials on Nov. 24th, 2020.

His PhD : Steady-state formulation of metal forming processes: Contact coupling and treatment of history-dependent material models with unstructured meshes

Shitij Arora conducted his thesis under the supervision of Lionel Fourment, who died after a long illness in November 2019. He completed it under the supervision of Pierre Montmitonnet.

He defends his PhD in Numerical Mechanics and Materials on November 24, 2020 in front of a jury composed of :

– D.R. Pierre MONTMITONNET, PhD Director

– Prof. Bert GEIJSELAERS Bert (Twente Univ. Drienerlolaan, Enschede, The Netherlands)

– Prof. Emmanuelle ROUHAUD (Troyes Univ. of Tech., Troyes)

– Prof. Jean-Philipe PONTHOT (Liege University, Liege, Belgium)

– M.R. Katia MOCELLIN (MINES ParisTech-CEMEF, Sophia Antipolis)

– Ing. Ugo RIPERT (Transvalor, Biot)

– Ing. Antoine COURTOUX (Arcelor Mittal)

Abstract:

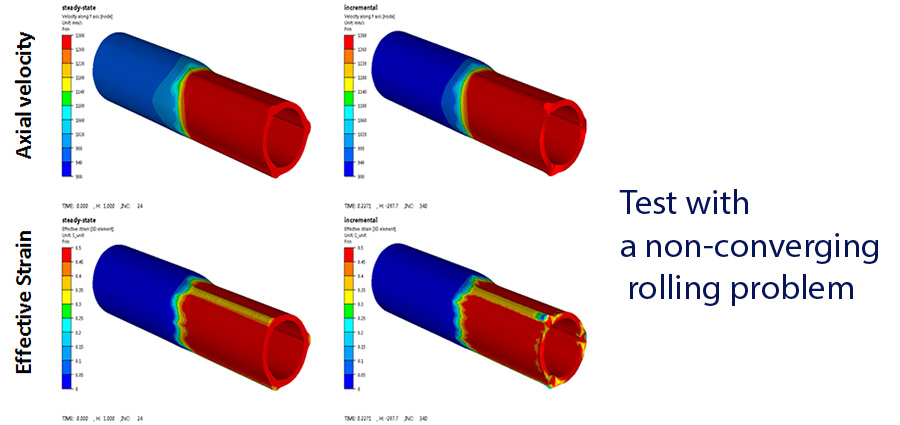

The existing Fg3stat formulation was proposed for the resolution of the steady-state hot forming processes with viscoplastic materials. The formulation comprises of a strongly-coupled multi-field problem and solved with a fixed-point iterative method. There are two main steps in the iterative algorithm: (i) a thermo-mechanical solver firstly computes the unknown velocity/pressure/Temperature field on a control volume (ii) a free-surface solver then computes the unknown steady-state shape. The Fg3stat, with unstructured meshes based on tetrahedral elements and parallelization with domain partitioning, is found to be at least 50 times faster than the traditional incremental approach for solving these processes. However, the formulation is not robust enough to find a stable solution especially with complex geometries. The work presented in this manuscript is focused on the improvement of the steady-state formulation with two main objectives. Firstly, a consistent contact-coupling is anticipated for a stable solution, and is achieved with a nodal condensation approach. The Explicit and Implicit consistent contact conditions are derived and the updated contact-coupling is tested with complex industrial hot-rolling test cases. Secondly, the original Fg3stat formulation was mainly focused only on hot forming problems with viscoplastic material models which do not consider elasticity effects. These effects become prominent in cold conditions and cannot be ignored. A pseudo-time-step approach makes possible to model the time in the time-independent formulation and is easily adaptable to the existing Fg3stat iterative algorithm. Though originally this approach used structured meshes for tracking streamlines, a new framework is developed to trace the streamlines in the unstructured meshes and to integrate the state-variables for solving the history-dependent problem. In each iteration, the state-variables must be transported from the streamlines to the mesh and vice-versa, which is generally diffusive. To restrict the diffusion, tools like SPR method for field smoothening and P1+ interpolation are invoked. The updated Fg3stat algorithm is tested with different cold rolling problems. The results from the hot and cold rolling simulations with the proposed algorithm are validated with the incremental (time-dependent) solution of the same problem in Fg3inc.

Keywords: steady-state modeling, contact formulation, multi-field formulation, cold rolling