PhD defence of Jules Baton

4 June 2021

Jules Baton defends his PhD in Numerical Mechanics and Materials on June 4th, 2021

Dislocation structures in cold deformed pure tantalum: evolutions and influences on recovery and recrystallization

Jules Baton conducted his PhD work in MSR team, under the supervision of Nathalie Bozzolo et Charbel Moussa and in the framework of research project with CEA. Jules Baton defends his PhD in Numerical Mechanics and Materials on June 4th, 2021 in front of the following jury:

Brigitte BACROIX, Directeur de recherche CNRS, Université Paris 13

Javier SIGNORELLI, Professeur, Universidad Nacional de Rosario

Andrea TOMMASI, Directeur de recherche CNRS, Université de Montpellier

Vladimir ESIN, Chargé de recherche, MINES ParisTech – Université PSL

Charbel MOUSSA, Chargé de recherche, MINES ParisTech – Université PSL

Nathalie BOZZOLO, Professeur, MINES ParisTech – Université PSL

Wilfried GESLIN, Ingénieur, CEA Valduc

Abstract:

Thanks to its high ductility at room temperature, pure tantalum is ideal for the cold forming of parts with complex geometries with minimal rupture risks. This thesis aims at understanding and providing a description of the physical mechanisms taking place during a plastic deformation and then an annealing.

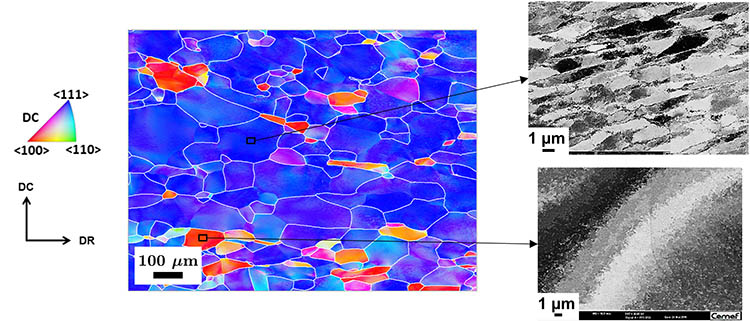

Various samples of pure tantalum were cold deformed by compression and rolling. The deformed microstructures were then characterized by scanning electron microscopy at grain and substructure scales. These characterizations revealed that the substructure development is strongly influenced by the crystallographic orientation of the grains and also by the texture of the initial state. In particular, γ-fiber grains form more substructures than θ-fiber grains. These differences cannot be correctly depicted only by dislocation density values. Parameters for the quantification of substructures have been proposed and their evolutions have been described by models.

Recrystallization is greatly impacted by the orientation dependence of the deformed state. Nucleation is promoted in γ-fiber grains due to the more advanced substructure development during deformation. This heterogeneity of behavior can be well described with stored energy estimated at substructure scale. Recovery has been studied directly and indirectly through its effects on recrystallization with various pre-recovery treatments. Two opposite effects on recrystallization were observed. A first non-contributive effect is related to the dislocation annihilation, which involves a decrease in the driving force for recrystallization. A second contributive effect is related to the enhancement of migration ability of subboundaries, which promotes nucleation. The balance between these two effects determines the overall effect of recovery on recrystallization. This balance varies depending on the deformation, the crystallographic orientation and the conditions of the pre-recovery treatment (time and temperature).

Keywords: Tantale, microstructure, dislocation structure, recovery, recrystallization