Theme: Research

Prof. Haudin named Fellow of the Polymer Processing Society

It is a great honor for Jean-Marc Haudin who since 1974 has dedicated his life to research in the field of polymer crystallization.

It is a great honor for Jean-Marc Haudin who since 1974 has dedicated his life to research in the field of polymer crystallization. Metallurgy in the spotlight with three SF2M 2020 awards

Our students and researchers in the spotlight! SF2M rewards three colleagues in 2020.

Among the twelve SF2M winners of the year 2020 are Daniel Pino Muñoz, Alexis Nicolaÿ and Artur Alvarenga. CEMEF's metallurgy activity is honoured and rewarded.

Congratulations to our three winners: Daniel Pino Muñoz, Alexis Nicolaÿ and Artur Alvarenga. The award ceremonies should normally take place during the annual SF2M days. The ceremony finally took place virtually on 17 December 2020. This does not take anything away from the talents of our recipients!

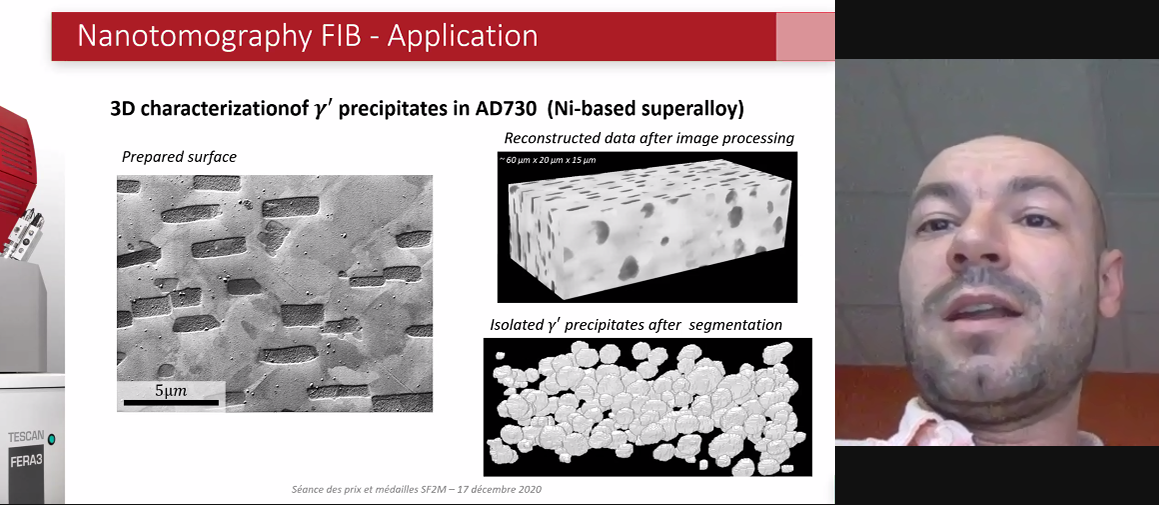

Daniel Pino Muñoz is a researcher in the CSM team. He is the recipient of the Jean Rist 2020 Medal. His research work focuses on the development of numerical tools to simulate microstructural evolutions in crystalline materials.

- The JeanRist Medal is awarded to 4 young metallurgists who have distinguished themselves by their scientific work applied to materials

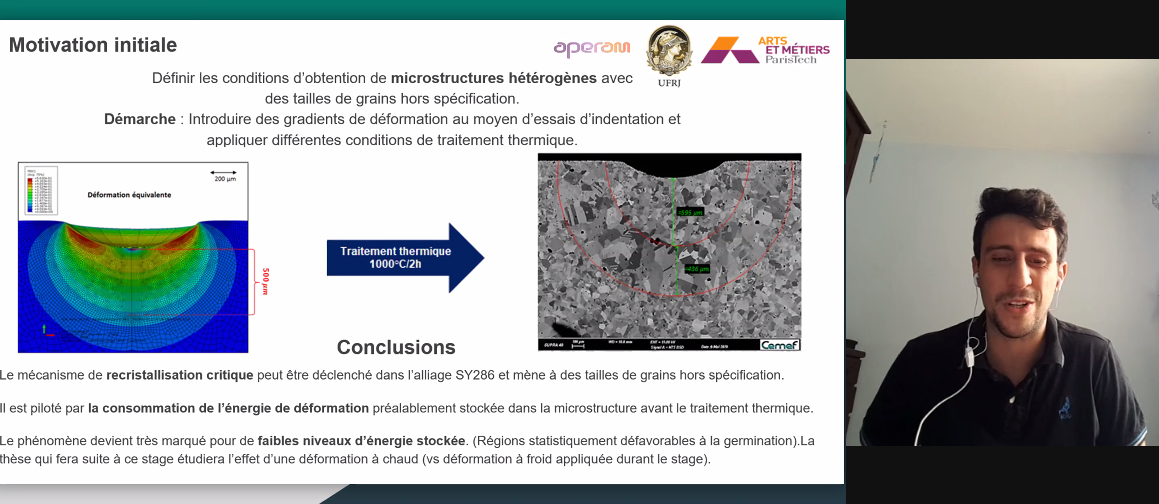

- The Bodycote Prize rewards innovative and application-oriented research and/or development work.

- The ArcelorMittal Pierre Vayssière Prize is awarded to a student who has completed an internship in an industrial or university laboratory.

WCCM Eccomas Arts & Science contest Public Award

Brayan Murgas is at the origin of this magnificent composition made from images from his work.

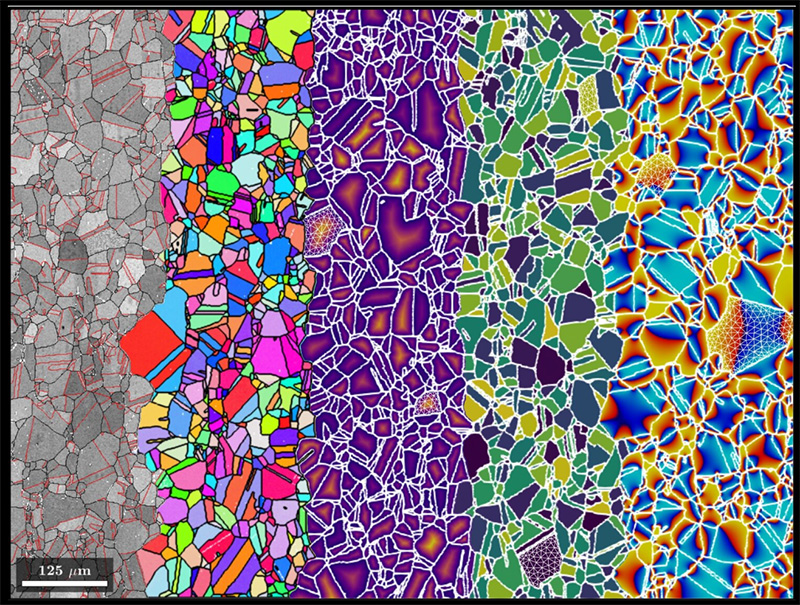

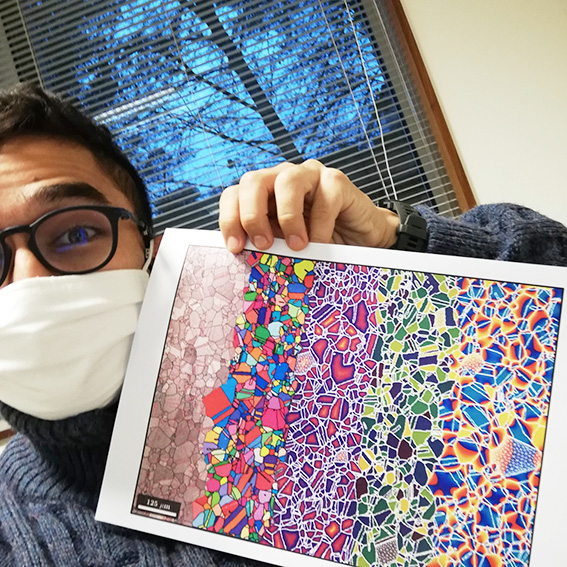

Congratulation Brayan Murgas! This image is both scientifically meaningful and aesthetically very successful. No wonder it caught the public's interest when it was awarded the "Arts & Science Contest" prize at the WCCM Ecomas International Conference held online last week.

Brayan Murgas is a 3rd year doctoral student in the MSR team. He is working on a fine description of the mobility of grain joints for its numerical integration in finite element simulations of recrystallisation mechanisms.

The origin of this image began when I started his PhD at CEMEF.

Brayan received his laptop and was looking for a wallpaper. He came up with the idea to do it by himself with the images he obtained from his first simulations.

To improve the Finite Elements modes, he uses Scanning Electron Microscopes allowing to properly describe grain boundaries.

The images used here represent the steps to immerse EBSD data into a Finite Element code: the Band contrast map which is an EBSD pattern that describes the average intensity of the Kikuchi bands.

The kikuchi bands are formed by electron scattering and describes the orientation of every pixel which is represented in the form of an inverse pole figure in the second slice of the image.

Finally he uses the orientation data of every pixel to construct the three last slices of the image: distance, orientation and grain boundary mobility fields.

With this methodology he can directly compare his results to experimental data and also he replaces in-situ experiments which are time consuming and difficult to perform.

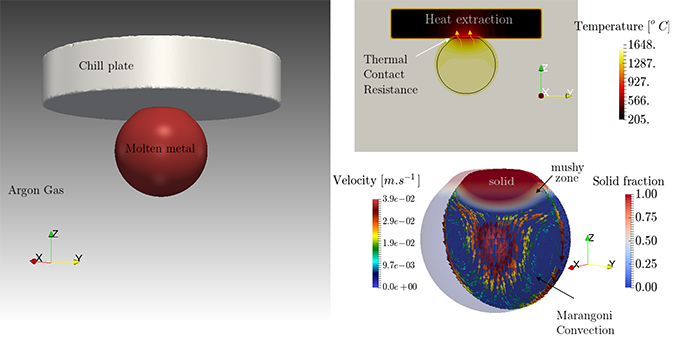

PhD defence of Ayoub Aalilija

Ayoub Aalilija defends his PhD in Numerical Mechanics and Materials on Dec. 21, 2020.

Numerical modelling of chill cooling of levitated steel melts solidified in the International Space Station

Ayoub Aalilija conducted his PhD work in 2MS team, under the supervision of Charles-André Gandin in the framework of ESA, the European Space Agency. He defends his PhD in Numerical Mechanics and Materials on Dec. 21, 2020 in front of the following juy:

PhD Defence of Vincent Maguin

Vincent Maguin defends his PhD in Numerical Mechanics and Materials on Nov. 16th, 2020.

"Multiphysic model of macrosegregation and development of freckles during solidification of single crystal turbine blades"

=> Animation with 90° rotation

PhD Defence of Benoît Wittmann

Benoît Wittmann defends his PhD in Numerical Mechanics and Materials on Nov. 17th, 2020.

"Materials and processes of the micro and macro texturation of floor covering surfaces, optical and tribological properties"

Benoît Wittmann conducted his thesis work in PSP team under the supervision of Pierre Montmitonnet, in the framework of a CIFRE project with Tarkett company.

He will defend his PhD work in Numerical Mechanics and Materials on Dec. 17th, 2020 in front of this jury: