Theme: Research

Best presentation award for George El Haber at CFC2023

Congratulations to George El Haber, 3rd year PhD student, whose research work has just been awarded.

Here are few words of George about his experience at the conference:

For me, the most exciting part wasn't the presentation itself but rather the discussion that followed my presentation. Getting feedback from experienced researchers who you used to read their papers, all gathered in a single room, and being able to discuss with them and answer their concerns, really motivates you to build on your current work and work towards new objectives. In reality, the conference, as a whole, is going to be indeed a remarkable and memorable experience in my academic journey.

>> More details on the CFC2023 Conference

>> IACM website

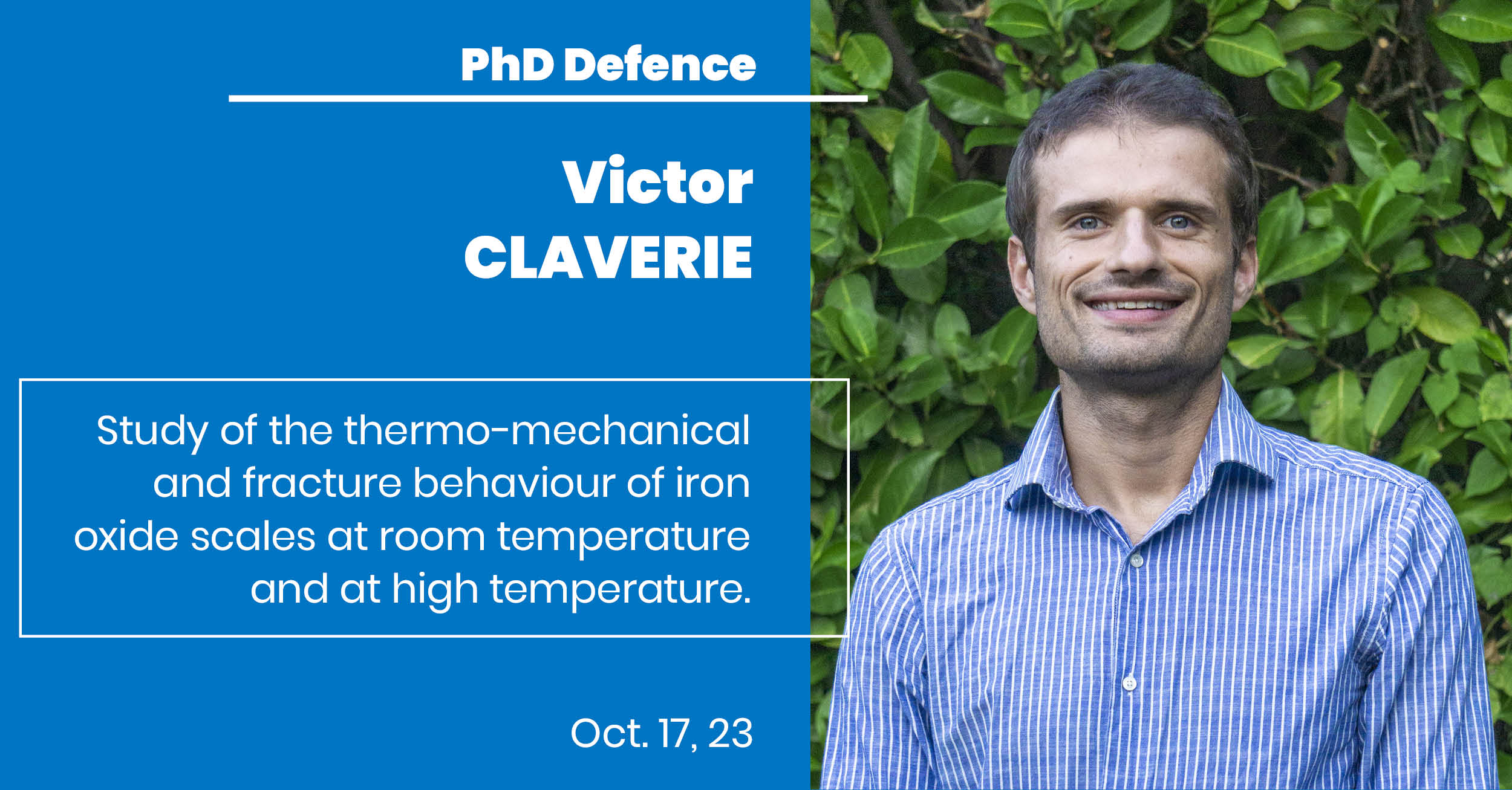

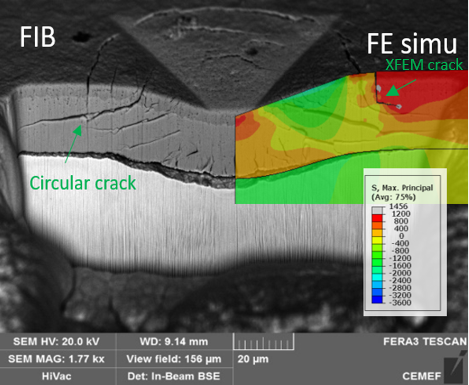

PhD defence of Victor Claverie

Victor Claverie defends his PhD in Computational Mechanics and Materials on Oct. 17, 23.

Study of the thermo-mechanical and fracture behaviour of iron oxide scales at room temperature and at high temperature.

Victor Claverie conducted his PhD work under the supervision of Pierre Montmitonnet and Karim Inal, PSF team. He defends his PhD in "Computational Mechanics and Materials" on October 17th, 2023 in front of the following jury:

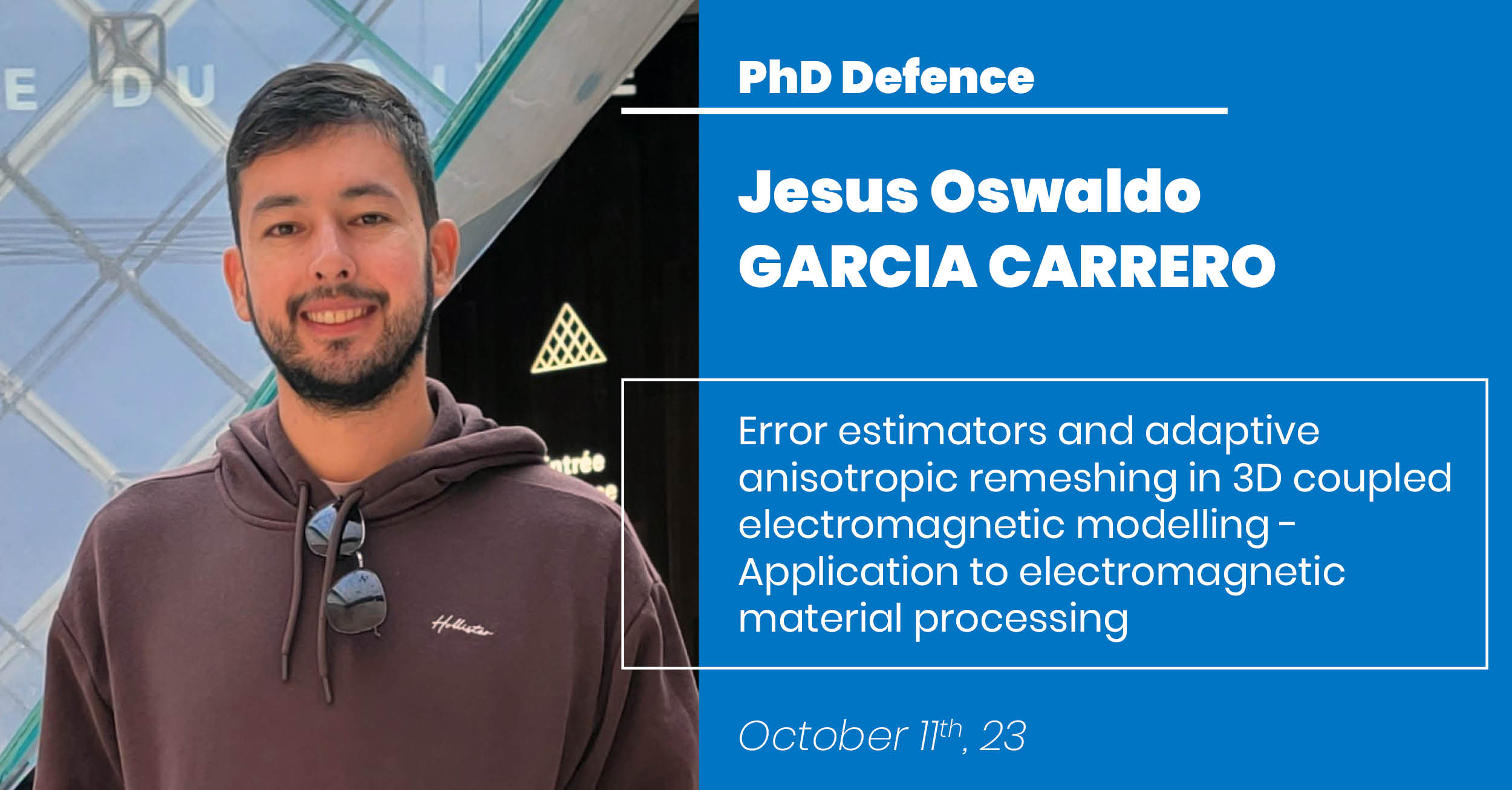

PhD defence of Jesus-Oswaldo Garcia Carrero

Jesus-Oswaldo Garcia Carrero defends his PhD in Computational Mechanics and Materials on Oct. 11, 23.

Error estimators and adaptive anisotropic remeshing in 3D coupled electromagnetic modelling – Application to electromagnetic material processing.

Upcoming conference: ICTP2023, sept. 24-29

CEMEF coorganizes the International Conference on the Technology of Plasticity in Mandelieu

PhD defense of Ghaniyya Medghoul

Ghaniyya Medghoul will defend her PhD in Computational Mathematics, High Performance Computing and Data on Jan. 16, 23

A posteriori error estimation and adaptive control for a finite element solver framework with dynamic remeshing: application to quenching process

Ghaniyya Medghoul conducted her PhD work in the CFL team under the supervision of Elie Hachem and Aurélien Larcher. She will defend her PhD in Computational Mathematics, High Performance Computing and Data, on January 16th, 23 in front of the following jury:

Abstract:

Keywords: a posteriori error estimation, stopping criterion, CFD modelling, anisotropic mesh adaptation, Non-smooth interpolation operators, stabilized finite elements

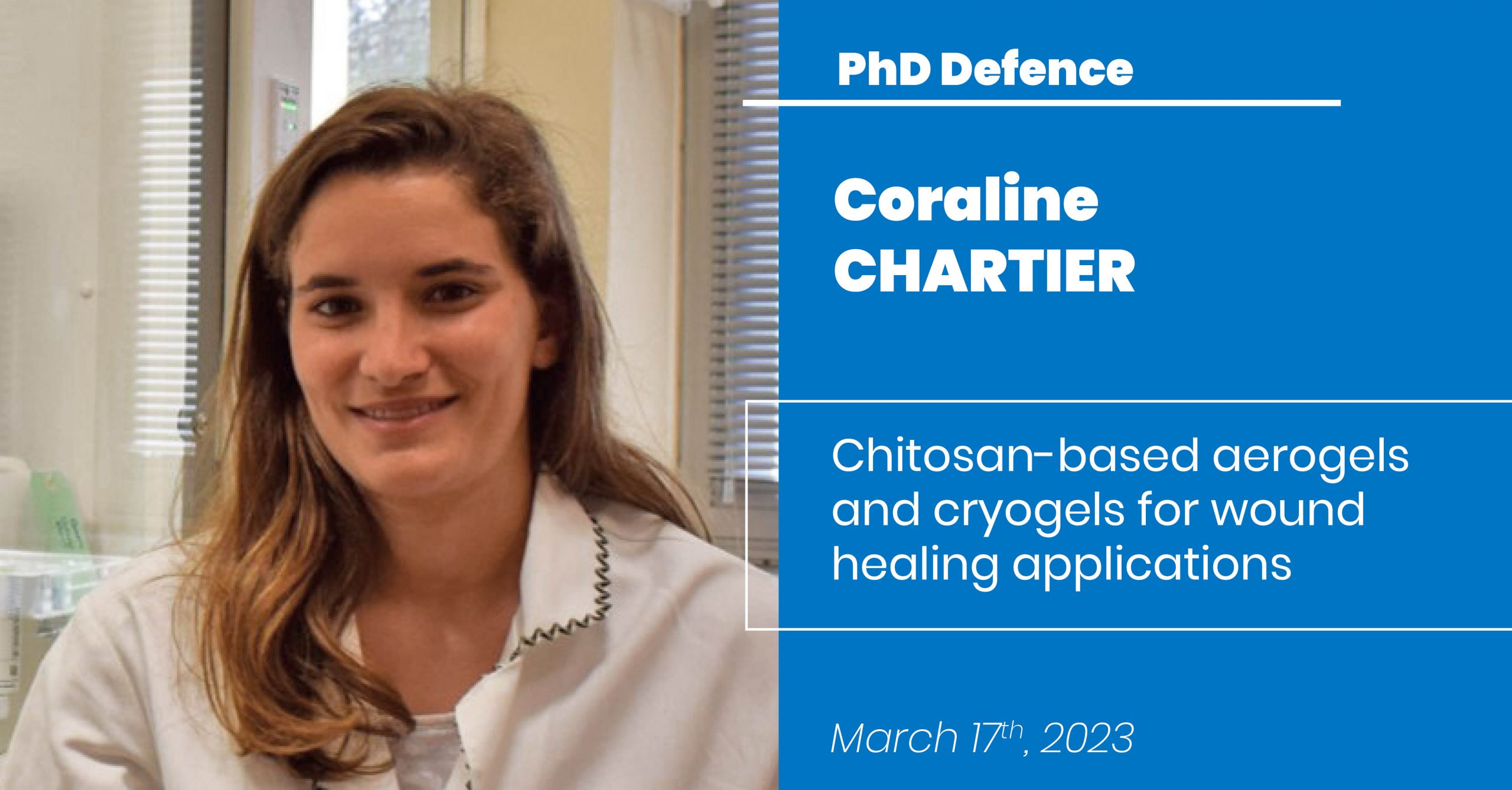

PhD defence of Coraline Chartier

Coraline Chartier defends her PhD in Computational Mechanics and Materials on March 17, 23.

Chitosan-based aerogels and cryogels for wound healing applications

Coraline Chartier conducted her PhD work in the BIO team under the supervision of Tania Budtova and Sytze Buwalda and with the Institute of Biomolecules Max Mousseron under the supervision of Benjamin Nottelet. She defends her PhD in "Computational Mechanics and Materials" on March 17th, 23 in front of the following jury:

Abstract:

Keywords: Aerogel, cryogel, chitosan, porous materials, controlled drug release, wound dressings