Physical mechanics of Industrial Polymers – MPI

permanent members

Jean Luc BOUVARD, head

Noelle BILLON

Christelle COMBEAUD

Lionel FREIRE

Gabriel MONGE

research fields

-Physical analysis and mechanical behavior of polymer / composite materials

-Development and control of microstructures under stretching

-Development of multi-scale strategies

-Thermomechanical modeling of polymer / composite behavior

applications

-Functional polymers and composites:

*Automotive and aeronautics

*Packaging

*Renewable energies

-Including bio-based and recycled polymers, elastomers, foams

Main objectives of the team

The objective of the team is to understand, characterize and model the mechanical behavior of polymers and composites from their solid to their rubbery states. This strategy is based on experimental methods and research equipment at the interface between mechanics and physics of polymers.

Relationship between process conditions and microstructure evolution is one of our main research axes. One application is for instance stretch blow molding and thermoforming processes.

Team's activity is also focused on the development and improvement of macroscopic physically based models used in finite element codes. The team develops multi-scale strategies through microstructure modeling to better understand structure-property relationships.

The different lines of research

Experimental mechanics applied to polymers: from the process ( e.g. extracting specimens in relation with specific microstructures) to final properties

- At the solid state: thermomechanical behavior, material performance and lifetime

- At the rubbery and viscous state: Stretching process; welding; additive manufacturing

Mechanical/microstructural coupling and microstructures evolutions

- Relation process– properties

- Control of microstructure and texturation under stretching

- Dimensional stability

Physically-based modeling and digital mechanics

- Development / improvement of macroscopic models established in a thermodynamic framework

- Taking into account thermo-hydro-… -mechanical coupling

- Improvement of existing models

- Development of multi-scale strategies: modeling of the microstructure and structure-property relationships

Examples of research work

Experimental resources

- Fast-cooling calorimeters, up to 500 ° C / min

- Optical microscopy assisted by stages (rapid cooling, shearing, etc.)

- X-ray diffraction at small and large angles; texture goniometer

- Dynamical mechanical analyser (D.M.T.A)

- Image correlation system (2D / 3D deformation field measurements) and Infrared thermography

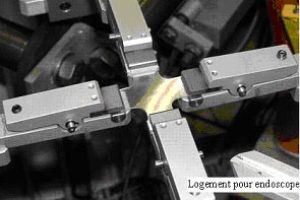

- Thermally controled biaxial stretching prototype

- Thermomechanical fatigue bench

- Free blow molding prototype

"My Ph.D. is on the shaping of a bio-based material for food packaging. My subject is being explored both academically and industrially in an innovative way!"

Emilie Forestier, PhD student at CEMEF

Academic Relations :

Institut Chimie Nice

LMA, Centre des Matériaux

ENSMA

Industrial Relations :

Solvay, Michelin, Arkema, Hutchinson

Danone, Avantium, Bel, Sidel

CEA, Essilor, Salomon, IPC, Renault, Safran

On going PhD projects

- Mekki GADDACHA : 3D crack propagation in a CMO/CMO interface at mesoscopic scale. Class of 2023 + MSR team

- Vincent MESLIER : Towards an improvement of the reliability of Photovoltaic modules by coupled experimental and numerical approaches. Class of 2021 + CSM team

- Alan TABORÉ : Modeling of residual stresses in an ophthalmic lens. Class of 2021 + CFL team

- Laurianne VIORA : Stretchability of chemically recycled PET. Class of 2020

- Zhongfeng XU : Multiscale study of polymer selective laser sintering (SLS) process: from characterization to numerical modelling. Class of 2020 + 2MS team