PhD Defense of Pierre-François Mougard-Camacho

1 March 2021

Pierre-François Mougard-Camacho defends his PhD in Numerical Mechanics and Materials on March 8, 21

Rheological studies on ceramic pastes for the shaping of nuclear fuels by extrusion

Pierre-François Mougard-Camacho completed his PhD thesis under the supervision of Rudy Valette and Romain Castellani, in the CFL team in the framework of a project with the CEA. He will defend his PhD thesis in front of the following jury:

– Christophe LANOS, Professeur, Université de Rennes

– Fabrice ROSSIGNOL, Directeur de Recherche, CNRS, Limoges

– Elisabeth LEMAIRE, Directrice de Recherche CNRS, Nice

– Julie BOURRET, Maîtresse de conférences, ENSCI, Limoges

– Romain CASTELLANI, Ingénieur de Recherche, Mines ParisTech

– Arnaud POULESQUEN, Chercheur Ingénieur, CEA Marcoule

– Franck DOREAU, Chercheur Ingénieur, CEA Marcoule

– Rudy VALETTE Professeur, Mines ParisTech

– Joumana YAMMINE-MALESYS, Directrice de Recherche, Weber St-Gobain

Abstract:

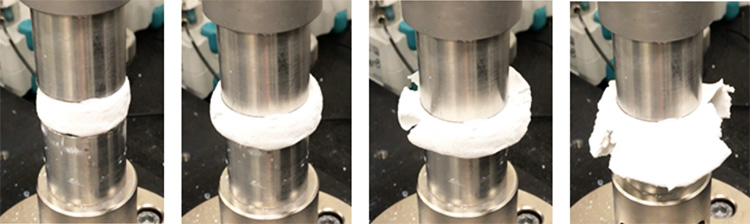

This work deals with the rheology of ceramic pastes, surrogate of MOX nuclear fuels (U,Pu)O2.. The thesis falls in the scope of ongoing research towards innovative processing methods to produce nuclear fuels. Fuels that have been produced by powder pressing so far.

A water-based formulation yielding defectless extrudates and mimicking a 30%at PuO2 fuel was engineered through the use of polymeric additives. The rheology of the paste was studied, followed by a characterization of the mechanical properties of extrudated and fired rods, in order to assess the feasibility of the process. Conventional capillary rheometry as well as an empirical model derived from ceramic extrusion, were combined to provide with satisfactory pressure predictions over wide operating conditions. Squeeze flow rheometry was also implemented to improve the formulation of pastes with adequate behaviour. Furthermore, it also enables a better control of the slipping conditions, as well as can enlighten liquid phase migration.

As a conclusion of this work, the production of nuclear MOX fuels by extrusion seems a promising alternative, which would be worthy of further studies in the future.

Keywords: Rheology, Ceramic, Extrusion, MOX fuel, Nuclear