PhD defence of Zixuan Li

Multiphysics Track-Scale Simulation of L-PBF 316L Additive Manufacturing: Thermo-Fluid Flow, Grain Growth, and Crystal Viscoplasticity

Zixuan Li conducted his doctoral research in the 2MS team under the supervision of Yancheng Zhang, Michel Bellet and Charles-André Gandin. He will defend his PhD in Computational Mechanics and Materials specialty on Dec 2nd, 2025 on:

Multiphysics Track-Scale Simulation of L-PBF 316L Additive Manufacturing: Thermo-Fluid Flow, Grain Growth, and Crystal Viscoplasticity

in front of the following jury:

M. Lionel GÉLÉBART, CEA, Reviewer

Mme Bai-xiang XU, Technical University of Darmstadt, Reviewer

M. Yabo JIA, LAMIH, University polytechnic hauts-de-France

M. Eric CHARKALUK, Laboratoire de mécanique des solides (LMS), École Polytechnique

M. Manas UPADHYAY, Laboratoire de mécanique des solides (LMS), École Polytechnique

M. Yancheng ZHANG, Mines Paris-PSL

M. Michel BELLET, Mines Paris-PSL

M. Charles-andré GANDIN, Mines Paris-PSL

Abstract:

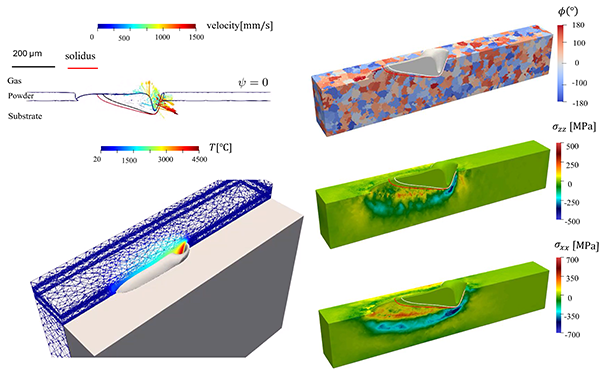

Laser Powder Bed Fusion (L-PBF) process enables the production of complex metallic components with excellent mechanical performance. However, the formation of columnar dendritic microstructures during rapid solidification induces strong mechanical anisotropy, and stress accumulation with possible solidification cracking. Understanding the mechanisms of these phenomena requires a comprehensive multiphysics approach that couples heat transfer, fluid dynamics, microstructure evolution, and crystal-scale mechanics. This study presents a coupled simulation framework in which fluid flow, grain structure evolution and solid mechanics are concurrently solved at each time increment. The melt pool behavior is simulated using a level-set-based finite element model that captures interface displacement and melt flow. Grain structure evolution in the mushy zone is described by a Cellular Automaton (CA) model, enabling prediction of columnar grain morphology and orientation. The stress field is computed using a Crystal Elasto-Viscoplastic (CEVP) formulation, which resolves slip-system-based deformation within individual grains to capture the track-scale anisotropic mechanical response. The model is applied to the L-PBF single and multi-track processing of stainless steel 316L. Track-scale simulations reveal interactions between microstructure development and stress generation, highlighting intra-grain heterogeneities and the crucial role of grain orientations and grain boundaries. This integrated approach provides new insights into the coupled thermo–metallurgical–mechanical behavior of metallic alloys in L-PBF and provides a sound background for the future development of more reliable prediction of solidification defects, but also the future development of activators to mitigate them in metallic additive manufacturing.

Keywords: Finite element method, Crystal Plasticity, Cellular Automaton, L-PBF