PhD defence of Zichen Kong

Wire laser additive manufacturing (WLAM): a multiphysics numerical simulation of heat transfer, fluid flow, and microstructure formation. Application to IN718 superalloy

Zichen Kong conducted her doctoral studies in the 2MS team Under the supervision of Gildas Guillemot, Michel Bellet and Charles-André Gandin. She will defend her PhD in Computational Mechanics and Materials on Dec. 15, 2025 on:

Wire laser additive manufacturing (WLAM): a multiphysics numerical simulation of heat transfer, fluid flow, and microstructure formation. Application to IN718 superalloy

in front of the following jury:

M. Mickael COURTOIS, Université de Bretagne Sud, Rapporteur

M. Daniel WEISZ-PATRAULT, École des Ponts ParisTech, Rapporteur

Mme Marion RISBET, Université de Technologie de Compiègne, Examinatrice

M. Christophe TOURNIER, ENS Paris-Saclay,Examinateur

M. Michel BELLET, Mines Paris – PSL, Examinateur

M. Gildas GUILLEMOT, Mines Paris – PSL, Examinateur

M. Charles-André GANDIN, Mines Paris – PSL, Examinateur

M. Denis SOLAS, Université Paris-Saclay, Examinateur

Abstract:

Wire Laser Additive Manufacturing (WLAM) is an additive manufacturing technique that produces large, high-value metallic parts from a metallic wire continuously melted by a laser. Its efficiency and high deposition rate make it an attractive alternative to powder-bed processes for manufacturing structural components in the aeronautics and energy sectors. However, controlling the geometric quality and microstructure of the deposits remains a major challenge, as these characteristics are strongly influenced by the thermal and hydrodynamic conditions within the melt pool, which themselves depend on the operating process parameters.

In this context, the doctoral work presented here, conducted within the ANR COLUMBO project, aims to develop a comprehensive numerical model for predicting thermo-hydraulic and microstructural evolution at the scale of a WLAM-deposited bead. The material studied is Inconel 718, a nickel-based alloy of industrial interest, selected for its excellent mechanical properties, its resistance to high-temperature corrosion, and its high elastic anisotropy coefficient—a parameter that strongly conditions the controllability of ultrasonic (US) methods. In addition, an original heating device using three converging laser beams, developed by the LURPA partner, was also implemented and investigated in this project.

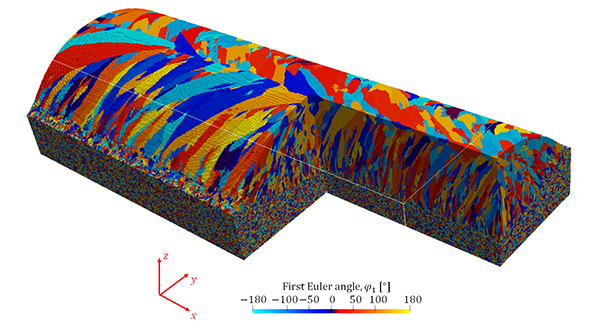

A volumetric source model, without explicit representation of the wire, is proposed to describe the mass and heat transfer associated with material addition. The thermo-hydraulic solution strategy, based on the finite element method, reproduces temperature distributions and melt-pool morphology as a function of process parameters (laser power, travel speed, wire feed rate, etc.). Its principal advantage is a significant reduction in computation time—from about one month to a few days—relative to studies reported in the literature for equivalent configurations, while maintaining a satisfactory level of accuracy. The thermal solution is coupled with a cellular automaton approach for predicting solidification microstructures, providing access to grain morphology and crystallographic orientation.

A parametric analysis on several single-track deposit configurations was carried out to assess the influence of process parameters on bead morphology and the resulting grain structure. The results showed good consistency with experimental observations for these simple deposition cases. The approach was then extended to multi-track configurations representative of industrial practice. In these more complex cases, larger discrepancies with experiments were observed, particularly regarding bead morphology, highlighting the model’s sensitivity to thermal interactions between passes as well as to wire delivery conditions.

Nevertheless, the methodology developed provides a robust and efficient numerical basis for predictive analysis and optimization of the WLAM process, offering an in-depth understanding of thermal mechanisms and microstructural evolution and thereby contributing to the progressive improvement of the process and the quality of the parts produced.

Keywrds: WLAM, Additive manufacturing, Solidification, Microstructure, CAFE modeling, Thermo-hydraulic