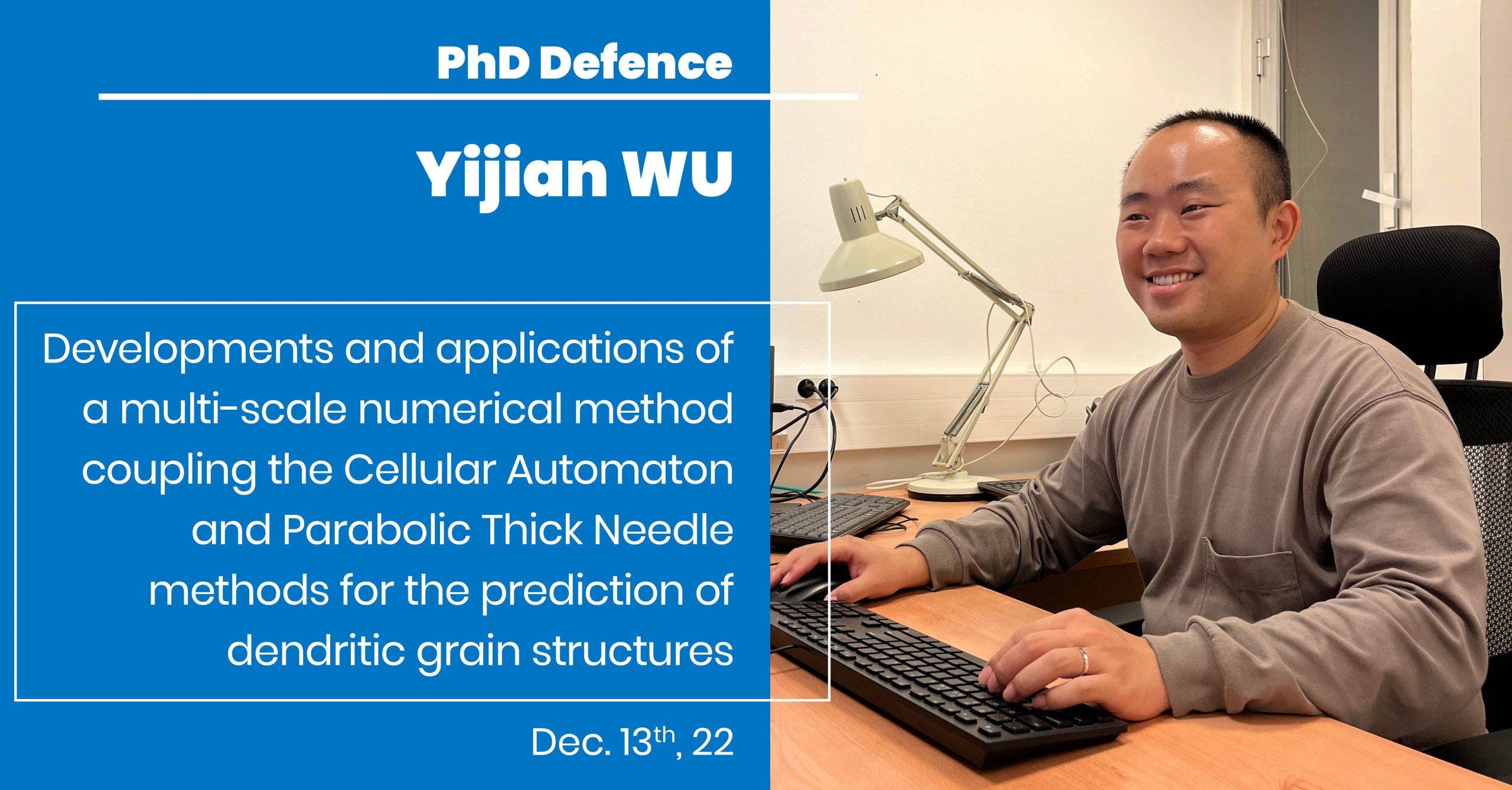

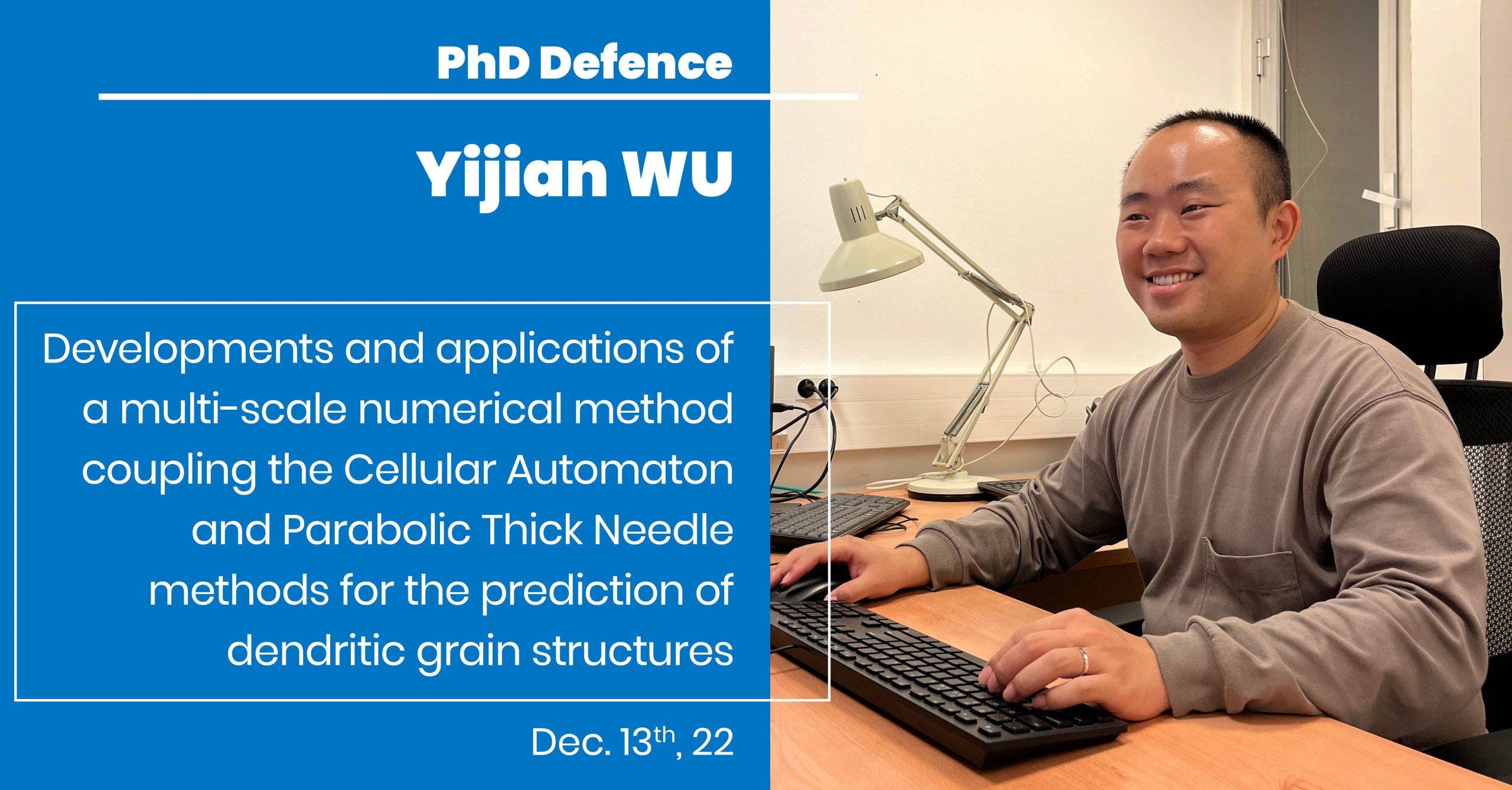

Yijian Wu defends his PhD in Computational Mechanics and Materials on Dec. 13, 22

Developments and applications of a multi-scale numerical method coupling the Cellular Automaton and Parabolic Thick Needle methods for the prediction of dendritic grain structures

Yijian Wu conducted his PhD work under the supervision of Charles-André Gandin and Oriane Senninger (2MS team). He defends his PhD in "Computational Mechanics and Materials" on December 13, 22 (subject to the agreement of the reviewers) in front of the following jury:

– Mr Henri Nguyen-Thi, Aix-Marseille Université, Reviewer

– Mrs Olga Budenkova, SIMaP, Reviewer

– Mr Mathis Plapp, Ecole Polytechnique, Laboratoire de Physique de la Matière Condensée

– Mr Charles-André Gandin, CEMEF Mines Paris – PSL

– Mrs Oriane Senninger, CEMEF Mines Paris – PSL

Abstract:

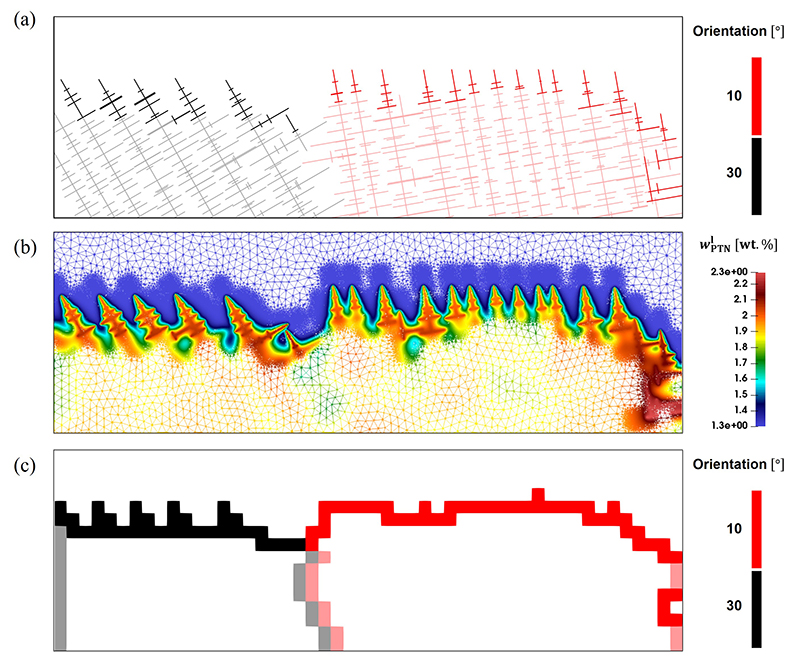

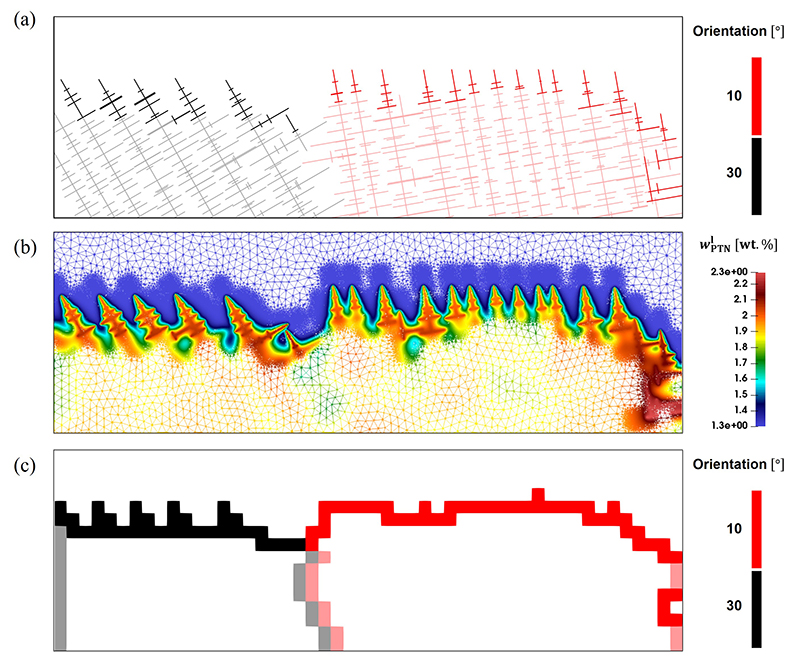

Numerical methods for modeling the microstructures formed during solidification are of great academic and industrial interest. The Cellular Automaton – Parabolic Thick Needle (CAPTN) method is a multiscale numerical method, which couples the Cellular Automaton (CA) and the Parabolic Thick Needle (PTN) methods, to simulate the growth of dendritic grains while accounting for non-steady diffusion fields. A dendritic branch is modeled as a cylinder headed by a parabolic tip. Its kinetics is computed using the PTN method from the composition field in the liquid in the vicinity of the parabola. This dendritic branch takes part in the definition of a grain envelope by its integration in a CA growth algorithm.

This thesis presents advances and computing optimizations on the multiscale CAPTN method. Indeed, at the beginning of the thesis, the CAPTN method was only implemented in two dimensions and was not numerically efficient. An adaptive heterogeneous meshing strategy and the orthogonal query method with the octree structure are therefore employed on the finite element implementation of the PTN method for increasing computational efficiency. The three-dimensional implementation of the PTN method is performed and evaluated through the analyses of convergence of simulation results to theoretical solutions depending on numerical parameters. Algorithmic improvements on the PTN method and the CAPTN coupling are also performed. The optimized three-dimensional CAPTN model is evaluated by modeling an equiaxed grain growing under constant supersaturation. The kinetics obtained by the CAPTN model is in good agreement with the kinetics obtained by the Phase-Field (PF) model and the Dendritic Needle Network (DNN) model. The optimized two-dimensional CAPTN model is evaluated on its ability to reproduce two physical quantities developed during directional growth in a constant thermal gradient with constant isotherm velocity: the primary dendritic arm spacing and the grain boundary orientation angle between two grains of different orientations. It is shown that the CAPTN model can reproduce the grain selection between primary branches and creation of new branches from tertiary branches as long as cell size is sufficiently small to model solute interactions between branches. In these conditions, simulations converge toward a distribution of primary branches which depends on the history of dendrite branches, in agreement with experimental results and theory. Contrary to the classical CA model, the grain boundary orientation angle obtained in CAPTN simulations is stable with cell size and in good agreement with previous PF studies for various temperature gradients.

Keywords: solidification, modeling, multi-scale, Cellular Automaton, Parabolic Thick Needle, dendritic microstructure

Solidification front of the bi-crystal CAPTN simulation, presented by (a) needle network, (b) composition field in PTN finite element mesh, and (c) automaton cells