PhD defence of Victor Claverie

10 November 2023

Victor Claverie defends his PhD in Computational Mechanics and Materials on Oct. 17, 23.

Study of the thermo-mechanical and fracture behaviour of iron oxide scales at room temperature and at high temperature.

Victor Claverie conducted his PhD work under the supervision of Pierre Montmitonnet and Karim Inal, PSF team. He defends his PhD in "Computational Mechanics and Materials" on October 17th, 2023 in front of the following jury:

– M. Henri BUSCAIL, Université Clermont Auvergne – IUT du Puy-en-Velay, Rapporteur

– Mrs Muriel BRACCINI, Grenoble INP – SIMAP, Rapporteur

– Mrs Salima BOUVIER, UTC – Roberval, Examinateur

– M. Laurent LANGLOIS, Arts et Métiers – Campus de Metz – LCFC, Examinateur

– M. Pierre MONTMITONNET, Mines Paris CEMEF, Examinateur

– M. Karim INAL, Mines Paris CEMEF, Examinateur

Abstract:

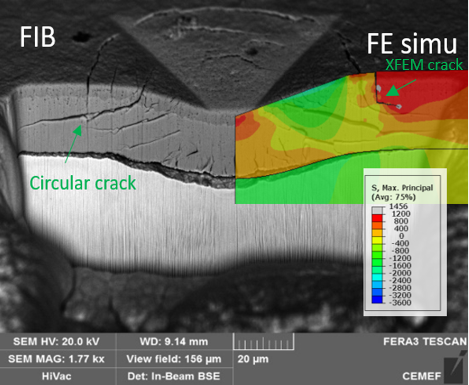

During the hot rolling process, a thin layer of oxide scale forms on the surface of steel slabs, leading to surface defects. Descaling, by applying high-pressure water to the steel surface, helps limit the thickness of the oxide and improve surface quality. This study aims to enhance the understanding of the phenomena involved in secondary descaling. Several low-carbon steel grades, characterised by differences in descaling, have been selected to analyse their discrepancies in industrial configurations. The behaviour of the oxide scale is evaluated through in situ high-temperature X-ray diffraction, enabling control over oxidation. This analysis includes both phase and stress evaluations to observe transitions in the behaviour of the oxide, particularly the relaxation of internal stresses above 700°C. Mechanical properties of the oxide are determined through indentation tests conducted at both room temperature and elevated temperatures. At lower temperatures (<600°C), indentation-induced cracks manifest in different patterns, consistent with a model of a hard film (the oxide) bending on a soft substrate (the metal), such as circular cracks and delamination. As the temperature increases, the oxide becomes ductile. Concurrently, numerical finite element simulations (FEM) of the indentation process are conducted to elucidate the mechanisms of fracture within the oxide layer. These simulations aim to extract essential fracture properties of the oxide layer and its interface. The acquired data will be used to develop a comprehensive model for hydraulic descaling.

FIB cross-section of an oxidized steel specimen after a 5N indentation and the corresponding XFEM simulation to model the fracture behavior of oxide

Keywords: iron oxide, descaling, indentation, numerical simulation, X-Ray Diffraction, hot rolling