PhD defence of Théophile Camus

Théophile Camus defends his PhD in Computational Mechanics and Materials on May 23rd, 2023.

Théophile Camus conducted his PhD work under the supervision of Charles-André Gandin, Gildas Guillemot and Oriane Senninger (2MS team). He defends his PhD in "Computational Mechanics and Materials" on May, 23, 23 in front of the following jury:

Abstract:

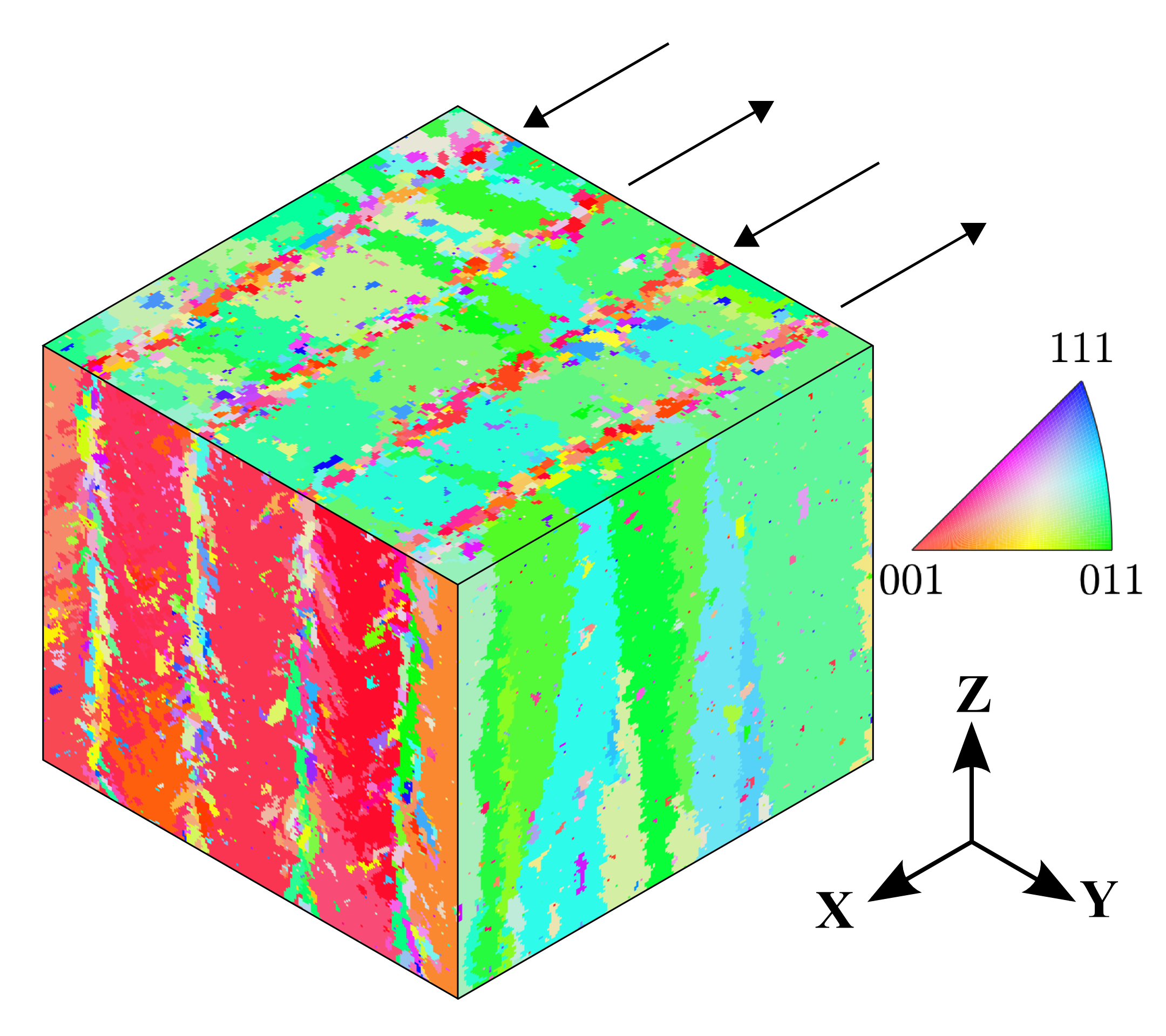

The laser powder bed fusion (LPBF) process makes it possible to produce metal parts with complex geometries and high added value. Its principle is based on the selective melting, using a laser, of successively stacked powder beds. The main applications of this additive manufacturing process concern the aeronautics and aerospace domains, for which Inconel 718 nickel-based superalloy parts are frequently produced. Mastering the mechanical properties of parts produced with LPBF process is therefore essential. These strongly depend on the microstructures generated during the successive solidifications occurring at the different layers. The microstructure is linked to the thermal conditions during solidification, directly influenced by the process parameters such as the laser power, its velocity, or its trajectories on the powder bed. In order to control the mechanical properties, it is necessary to control the development of the microstructures of the manufactured parts by working on the manufacturing parameters. As part of this research work, a finite element thermal-hydraulic model of the lasing of a powder bed is used to describe the thermal behavior as a function of process parameters, and a Cellular Automaton model is used for the prediction of grain structures. The thermal model requires high computation times, a new hybrid methodology is therefore developed to benefit from the stationary temperature field obtained by multiphysics simulation, on multi-pass multi-layer fabrications. The advantage is to reach a large size of the microstructure simulation domain while benefiting from a complete numerical solution of the process at the scale of the melt pool. Applied to different process parameters, it is possible to measure the influence of each parameter on the generated microstructures in representative elementary volumes. Thus, the understanding of the formation of microstructures in LPBF is improved thanks to these models.

Keywords: Microstructures, Modeling, Additive manufacturing, Laser powder bed fusion, Solidification, Inconel 718

Grain structure obtained by Cellular Automaton modelling of the LPBF process in a representative elementary volume