PhD defence of Sujie Yu

From Cellulose Ethers to Bio-Aerogels: Toward Additive Free Drug Carriers

Sujie Yu conducted her doctoral research under the supervision of Tatiana Budtova and Rudy Valette. She defends her PhD in Computational Mechanics and Materials specialty on July 11, 2025 in front of the following jury:

M. Mohamed Naceur BELGACEM, Grenoble INP – Institut polytechnique de Grenoble, Reviewer

M. Carlos Alberto GARCíA-GONZALEZ, Universidade de Santiago de Compostela, Reviewer

M. Michel DUMON, Université de Bordeaux, Examiner

Mme Lara MANZOCCO, University of Udine, Examiner

M. Rudy VALETTE, CEMEF, Mines Paris-Université PSL, Examiner

Mme Tatiana BUDTOVA, CEMEF, Mines Paris-Université PSL, Examiner

Abstract:

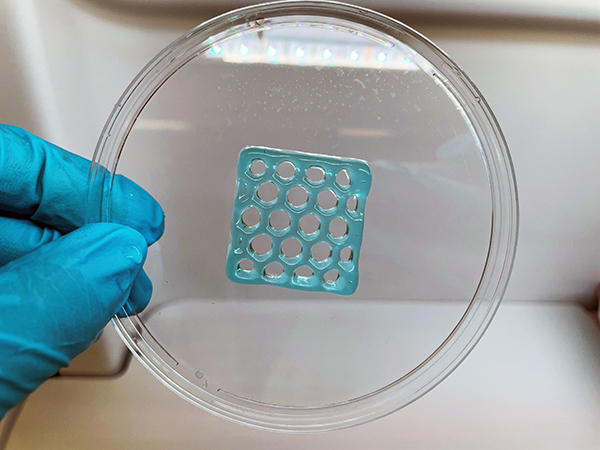

This thesis explores the potential of neat cellulose ethers, particularly carboxymethyl cellulose (CMC) and methylcellulose (MC), for making aerogels aimed at drug delivery applications and complex shape manufacturing via 3D printing. Despite the widespread use of cellulose ethers in medicine and industry, neat CMC or MC aerogels remain scarcely explored. Lightweight aerogels with high specific surface area (up to several hundred m²/g) were prepared through non-solvent induced phase separation followed by supercritical CO₂ drying. Alternative drying routes, such as freeze-drying and evaporative drying, were also used to produce cryogels and xerogels for comparative analysis. The structure and morphology of the materials were thoroughly characterized, and drug release behavior was assessed using a model drug (L-Ascorbic acid 2-phosphate) in simulated wound exudate. The results demonstrate that both CMC and MC aerogels are promising candidates for drug delivery. Mechanical properties of CMC aerogels and cryogels were evaluated via uniaxial compression tests combined with digital image correlation. Direct ink writing was successfully applied to neat CMC solutions without any additives or crosslinking, only by adjusting solutions’ rheological properties. Aerogels were then made from the printed structures through drying with supercritical CO2. These findings provide an important basis for the design and manufacturing of customized biopolymer porous scaffolds for drug delivery, tissue engineering, and other related applications.

Keywords: aerogels, cellulose ethers, porous materials, drug release, mechanical properties, direct ink writing