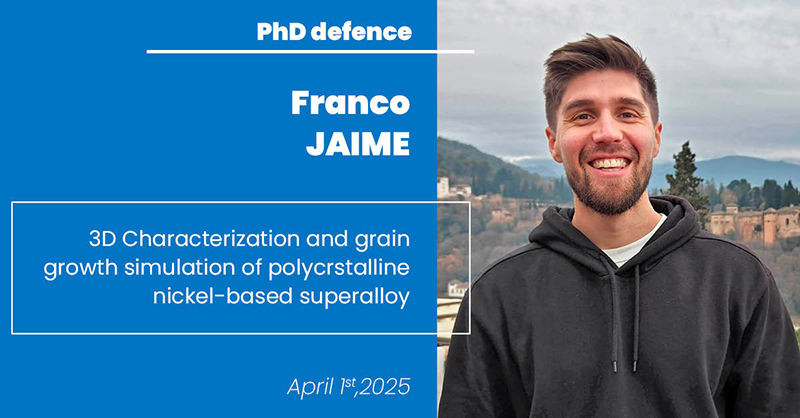

PhD defence of Franco Jaime

3D Characterization and grain growth simulation of polycrstalline nickel-based superalloy

Franco Jaime conducted his doctoral research in the MSR research team, in the framework of the ANR French Agency Industrial Chair Topaze. Franco defends his PhD in Computational Mechanics and Materials specialty on April 1st, 2025 in front of the following jury:

M. Andras BORBELY, Mines Saint-Étienne

M. Philippe VENNEGUES, CRHEA

M. Henry PROUDHON, Centre des Matériaux – Mines Paris – Université PSL

M. Pierre-Henri JOUNEAU, CEA

M. Marc BERNACKI, CEMEF Mines Paris

Mme Nathalie BOZZOLO, Safran Tech

M. Alexis NICOLAY, Cemef – Mines Paris – Université PSL

Mme Anne DELOBBE, Orsay Physics

M. Daniel GALY, Safran Tech

Abstract:

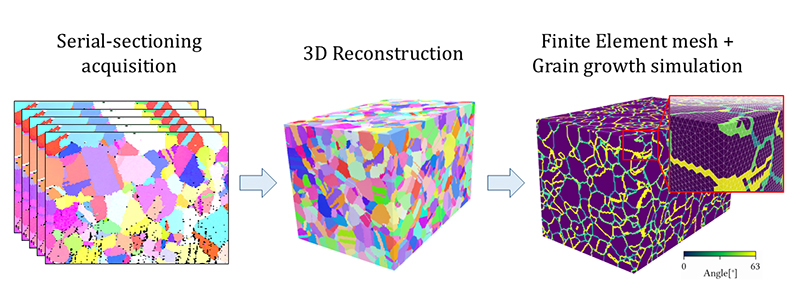

This PhD thesis focuses on the development and application of advanced 3D characterization and simulation techniques for Inconel 718, a nickel-based superalloy used in aircraft engines. Two metallurgical states are studied: an equiaxed microstructure and an additively manufactured microstructure after thermal treatment. A dual-beam PFIB-SEM is used to develop and optimize serial-sectioning protocols for the equiaxed state, while mechanical polishing coupled with EBSD is employed for the additively manufactured state. The acquired EBSD maps are processed for 3D reconstruction, and guidelines for this workflow are outlined. Reconstructed microstructures are integrated into a finite element framework to study the effects of meshing strategies on grain boundary topology, emphasizing voxelization limitations. Isotropic and heterogeneous grain growth simulations are conducted using different grain boundary properties models, even incorporating twin boundaries. Finally, 2D and 3D simulations are compared, analyzing differences in grain growth topology and grain size distribution evolutions.

Keywords: Serial-sectioning, Nickel-based superalloys, Full-field simulation, Grain growth

Schematic representation of the procedure for obtaining a meshed microstructure from a set of electron backscattered diffraction (EBSD) analysis obtained by serial-sectioning. Beginning with the stack of images obtained as a result of the serial-sectioning, passing by the 3D reconstruction of the microstructure and finishing in a FE mesh