PhD Defence of Federico Orlacchio

Evolution of the microstructure of the nickel-based superalloy γ-γ’ René 65 during hot forging for the manufacture of turbine disks

Federico Orlacchio conducted his PhD research in the MSR research teamp, supervised by Marc Bernacki, Daniel Pino Munoz and Madeleine Bignon, in the framework of a CIFRE convention with SAFRAN. He will defend his PhD in Computational Mechanics and Materials on December 5th, 2024, in front of the following jury:

Mme Florence PETTINARI-STURMEL Université Paul Sabatier et CNRS Reviewer

M. Guillaume KERMOUCHE École des Mines de Saint-Étienne Reviewer

M. Alain HAZOTTE Univeristé de Lorraine

M. Bernard VIGUIER CIRIMAT – INP/ENSIACET, Université de Toulouse

M. Marc BERNACKI PSL MINES Paristech, CEMEF

M. Daniel PINO MUÑOZ PSL MINES Paristech, CEMEF

Mme Madeleine BIGNON PSL -MINES Paristech, CEMEF

Mme Nathalie BOZZOLO Safran Tech

M. Chi-Toan NGUYEN Safran Tech

Abstract of his research work:

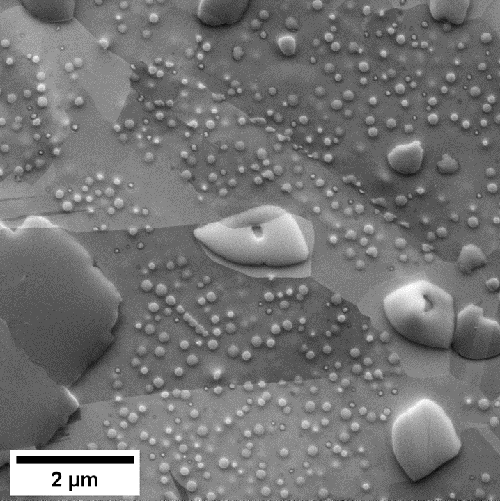

Nickel-based superalloys are high-performance metallic materials offering excellent mechanical properties at high temperatures. For this reason, they are widely used in the aerospace industry for the hottest, most highly stressed parts of jet engines. To increase operating temperature and, at the same time, reduce fuel consumption and greenhouse gas emissions, the nickel-based polycrystalline superalloy γ-γ’ René 65 has been chosen for the manufacture of certain turbine disks in new-generation turbojet engines. In service and during hot forming, this family of superalloys features two distinct phases: γ, a Ni-rich solid solution, and γ’, an intermetallic compound with a stoichiometric Ni3(Al,Ti) composition. During forging, both phases can evolve simultaneously, with comparable kinetics and different possible interaction mechanisms such as Smith-Zener pinning and heteroepitaxial recrystallization, making the study of underlying microstructural evolutions complex and ambitious. The main objective of this work is to study the microstructural evolutions at work during the various hot forging operations for the two phases, γ and γ’, using a mainly experimental approach. To achieve this, a themomechanical path with subsolvus heat treatment, followed by hot compression and finalized by solution treatment, was reproduced in the laboratory. In the course of this work, the experimental dissolution kinetics of γ’ precipitates and the static recrystallization kinetics of the γ matrix during subsolvus treatment were determined. The effect of thermomechanical parameters such as deformation level, strain rate and temperature on dynamic recrystallization has been studied in detail in the subsolvus domain of the alloy. The evolution of the microstructure during solution treatment, i.e. in the grain growth regime, was analyzed from different initial microstructures. In addition, a mean-field grain growth model in the presence of γ’ precipitates was calibrated and validated for the René 65 alloy. This work provides a better understanding of the forging behavior of nickel-based γ-γ’ superalloys in the subsolvus domain, i.e. in a context of strong interaction and coupling between the γ matrix and γ’ precipitates. In conclusion, the results obtained are also industrially important for future optimization of the hot-forging process for this alloy.

Keywords: Nickel-based superalloys, γ-γ’ microstructures, γ’ precipitation, Recrystallization, Hot forging