PhD defence of Emile Hazemann

19 December 2022

Emile Hazemann defends his PhD in Computational Mechanics and Materials on Dec. 19, 22

Study of recrystallized grains occurence in single crystal nickel-based superalloys for turbine blades application

Emile Hazemann conducted his PhD work under the supervision of Charles-André Gandin, Michel Bellet, Yancheng Zhang (2MS team) and Karim Inal (PSF team). He defends his PhD in "Computational Mechanics and Materials" on December 19, 22 (subject to the agreement of the reviewers) in front of the following jury:

– M. Jonathan CORMIER, Institut P' CNRS-Université de Poitiers-ISAE ENSMA

– M. Carl LABERGERE, Université de Technologie de Troyes

– Mme Virginie JAQUET, Safran Aircraft Engines

– M. Roland FORTUNIER, Ecole Nationale d'Ingénieurs de Saint Etienne

– Mr Charles-André Gandin, CEMEF Mines Paris – PSL

– Mr Michel Bellet, CEMEF Mines Paris – PSL

– Mr Karim Inal, CEMEF Mines Paris – PSL

– Mr Yancheng Zhang, CEMEF Mines Paris – PSL

Abstract:

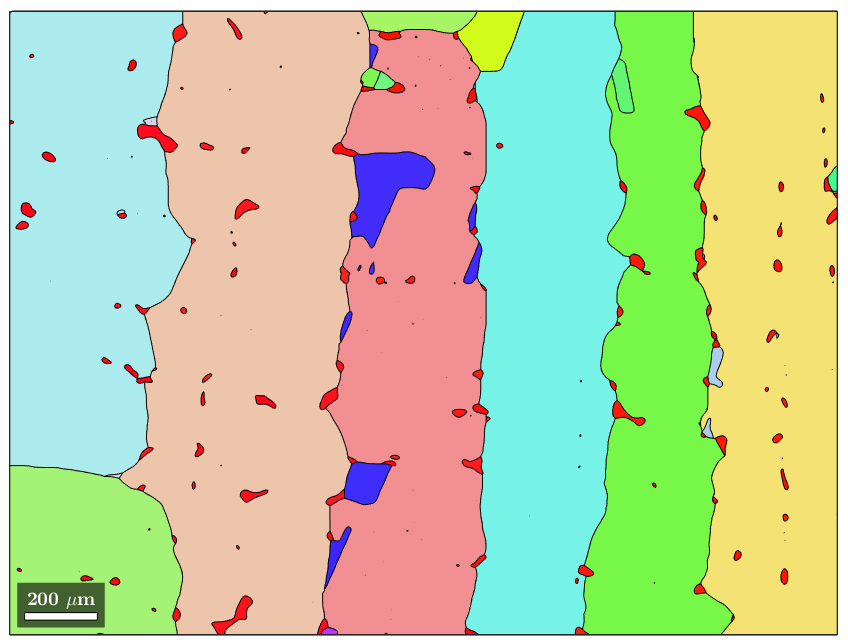

The current work’s aim is to understand recrystallized grains formation in single-crystal nickel-based superalloys for turbine blades application. The presence of such grains, with large misorientation compared to the single-crystal’s orientation, is prohibitive because it decreases dramatically the mechanical behaviour of the part. On one hand, nucleation of recrystallized grains is related to the amount of strain introduced in the alloy during solidification and cooling, and on the other hand, to subsequent heat treatment. To predict nucleation and growth of recrystallized grains, one needs to identify 1) the mechanical behaviour of the alloy during solidification and cooling 2) a recrystallization criterion based on the mechanical state of the matter. The present work is built around these two research axes, specifically for CMSX-4, a second-generation nickel-base superalloy. In the first axis, we identify as-cast CMSX-4 behaviour with an elastic viscoplastic constitutive law, using tensile-relaxation tests and finite elements modelling. The identified model considers single crystal anisotropy at temperatures and strains rates representative of casting process. The parameters of the constitutive laws are identified using inverse analysis, using tensile-relaxation tests, at constant temperatures, on as-cast CMSX-4 samples with tensile direction oriented along <001>, <110> and <111> crystallographic orientations. Tests are performed with a resistive heating machine, using contactless instrumentation (infrared pyrometry and digital image correlation). In the second axis, our interest is to reproduce thermomechanical paths of areas that are critical regarding recrystallization in a turbine blade, during solidification and cooling. These paths are simulated with tensile tests at different stress rates and a constant cooling rate, for specimens with different orientations. Tested specimens undergo standard homogenization heat treatment to reveal or not the presence of recrystallized grains. Thermo-mechanical paths are then simulated with constitutive law identified in the first axis, to identify a recrystallization criterion.

Keywords: Recrystallization, Mechanical behaviour, Nickel-based superalloys, Microstructure, CMSX-4, Modelling

Recrystallized microstructure in single-crystal CMSX-4 sample after tensile testing at approximately 1290°C and annealing at 1300°C for 19h.