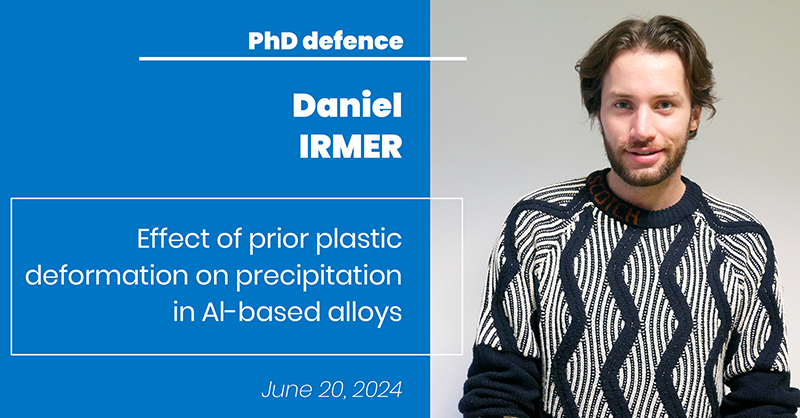

PhD defence of Daniel Irmer

Effect of prior plastic deformation on precipitation in Al-based alloys

Doctoral project of Daniel Irmer is in the framework of a cooperation between Centre des Materiaux and CEMEF. Daniel conducted his research under the supervision of Vladimir Esin and Mohamed Sennour (CMAT) and Charbel Moussa (CEMEF).

Daniel Irmer will defend his PhD of the ISME doctoral school on June 20, 2024 at Mines Paris.

Abstract:

In the pursuit of optimising industrial aluminium alloy production through complex thermo-mechanical treatments for improved efficiency and environmental sustainability, understanding microstructure development is crucial for adjusting final properties. The mechanical properties of precipitation-hardened alloys depend on the precipitation microstructure and the evolution of precipitates during service life determines its lifetime properties.

This thesis aims to further elucidate and, where possible, quantify the interaction between precipitation and deformation. AA2024, an aluminium alloy widely used in aeronautics, is studied in detail. AA2024 possesses a simple precipitation sequence including co-clusters, Guinier-Preston-Bagaryatsky (GPB) zones and the equilibrium S-phase, allowing the study of the deformation-precipitation interaction directly without interfering effects, such as changes in the precipitation sequence. The evolution of the precipitation microstructure during ageing in unstrained material was characterised by Transmission Electron Microscopy (TEM) and precipitate size distributions for a wide range of ageing conditions ranging from 85 to 250 °C and 1 to 10 000 h were obtained. A mean-field model (KWN) was used to describe precipitation kinetics in a temperature range from 120 to 250 °C. The mean precipitate size can be well described and a temperature dependence for the interfacial energy of nucleation, serving as a fit parameter, is obtained.

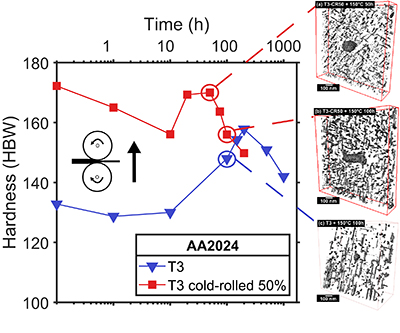

Precipitation during ageing in pre-strained samples was analysed and quantitatively compared with the state without pre-deformation. It was shown with Atom Probe Tomography (APT) analysis that co-clusters are dissolved by shearing during cold rolling and do not reconstitute during following natural ageing at ambient temperature. Increased hardness upon ageing was observed due to fine and homogeneously distributed precipitates. An In situ TEM analysis was carried out to study in detail the transition from heterogeneous precipitation on dislocations to a homogeneous distribution of precipitates. It was revealed in these studies that recovery as well as the spatial distribution of dislocations has an important impact on overall precipitation kinetics. While at the beginning of precipitation accelerated kinetics are observed, during on-going ageing towards severely over-aged states this effect phases out.

In this context the deformation microstructure after cold rolling in different sample states with shearable (co-cluster, GPB zones) and non-shearable (S-phase) precipitates was analysed in 2 and 3D using state-of-the-art Electron Backscatter Diffraction (EBSD) and synchrotron based Dark-field X-ray Microscopy (DFXM) analysis, respectively. Sub-boundaries were higher in density but lower in disorientation angles with the presence of non shearable precipitates.

Higher and more alternating long-range orientation gradients in both 2D and 3D analyses were observed at medium strain in material with non-shearable precipitates, impeding dislocation glide. At higher strains, 2D analysis revealed a progressive increase in long-range orientation gradients in material with shearable precipitates only, suggesting the potential role of S-phase precipitates in impeding sub-boundary assembly and grain fragmentation. The stored energy, as an acting driving force for recovery and recrystallisation, was found to increase due to the presence of non-shearable precipitates during deformation, impacting the recovery behaviour, as X-Ray texture analysis suggests.

In total, the analyses contribute to knowledge about the interaction of deformation and precipitation at different parts of the production process or assembly of industrial aluminium alloys. Based on this insight tailored thermo-mechanical treatments can be developed in subsequent research projects, the ground laying mechanisms might be applied for other precipitation hardened alloy types as well.

Effect of cold rolling on AA2024-T3 (solutionised, quenched, 3% strained and naturally aged) on hardness during subsequent heat treatment at 150 °C. Hardness is accompanied by selected electron tomographies after (a) 50 h and (b) 100 h of heat treatment on the cold-rolled state, illustrating precipitation on dislocation lines in (a) leading to fine and homogeneously distributed precipitates in (b) compared to the unstrained state after 100 h of heat treatment in (c)

Keywords: precipitation, recovery, deformation, diffusion, aluminium alloys, sub-structures