PhD defence of Ayoub Aalilija

17 December 2020

Ayoub Aalilija defends his PhD in Numerical Mechanics and Materials on Dec. 21, 2020.

Numerical modelling of chill cooling of levitated steel melts solidified in the International Space Station

Ayoub Aalilija conducted his PhD work in 2MS team, under the supervision of Charles-André Gandin in the framework of ESA, the European Space Agency. He defends his PhD in Numerical Mechanics and Materials on Dec. 21, 2020 in front of the following juy:

Full P. Emmanuelle ABISSET-CHAVANNE (ENSAM Bordeaux-Equipe Trefle-I2M, Talence) : rapporteur

Assoc. Prof. Douglas MATSON (Tufts School of Eng. Robinson Hall, Medford, Etats-Unis) : rapporteur

Pr. Catherine COLIN (Inst. Nat. Polytechnique de Toulouse-Inst. Meca. des Fluides, Toulouse) : examinateur

Pr. Elie HACHEM (MINES ParisTech-CEMEF, Sophia Antipolis) : examinateur

Abstract:

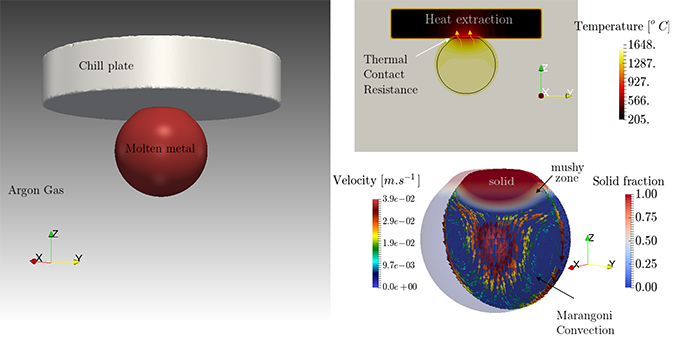

The study of solidification in microgravity allows researchers to dissociate gravity-independent phenomena from gravity-dependent ones. The objective is to reach a better understanding of solidification allowing the metallurgical industry to meet the expected properties of their metal products and to avoid the defects that appear during their elaboration. In this context, the NEQUISOL and CCEMLCC projects of the European Space Agency are taking place. As part of these two projects, we propose a numerical framework to simulate the solidification experiments of metallic samples in electromagnetic levitation in the International Space Station. Our numerical tool is based on the finite element resolution of the conservation equations of energy, total mass, momentum and mass of the chemical species of a multi-domain system involving a multicomponent metal alloy. A monolithic formulation allows the resolution of one set of equations on a single Eulerian mesh. A stabilised VMS Finite Elements formulation is proposed to solve the Navier-Stokes equations. The modelling is enriched by taking into account solidification shrinkage, surface tension and the Marangoni effect acting at the liquid-gas interface. A contact thermal resistance model is developed and validated enabling the consideration of thermal contact imperfections between the different materials. The Level Set method is used to model the interfaces between the sub-domains. The liquid-solid interface within the metal sub-domain is implicitly represented by the volume average methodology. In a first step, we propose simulations of measurement experiments of surface tension and viscosity of liquid metals using the oscillating drop technique in microgravity. This benchmark offers a quantitative comparison between the numerical results and an analytical solution that we derived in both 2D and 3D. Once we have validated our numerical modelling of the dynamics of the liquid-gas interface, we perform simulations of the solidification of a steel droplet and compare it with data from the first and unique experiment performed on board the International Space Station in the framework of the CCEMLCC project.

Keywords: Numerical simulation; Finite Element; Level Set; Surface tension; Marangoni; Thermal contact resistance; Oscillating drop; Solidification; Microgravity