PhD defence of Antonio Potenciano Carpintero

Heterogeneous grain growth in the iron-based superalloy A-286

Antonio Potenciano Carpintero conducted his doctoral research in the MSR research team. He defends his PhD in Computational Mechanics and Materials specialty on April 2nd, 2025 in front of the following jury:

Mrs Myriam DUMONT, ENSAM Lille

Mr. Alain HAZOTTE, Université de Lorraine

Mr. Laurent DELANNAY, Université Catholique de Louvain

Mrs Nathalie BOZZOLO, Safran

Mr. Marc BERNACKI, MINES Paris

Mr. Alexis NICOLAÿ, MINES Paris

Mr. Jonathan DAIRON, Aperam

Mrs Olena DANYLOVA, Aperam

Abstract:

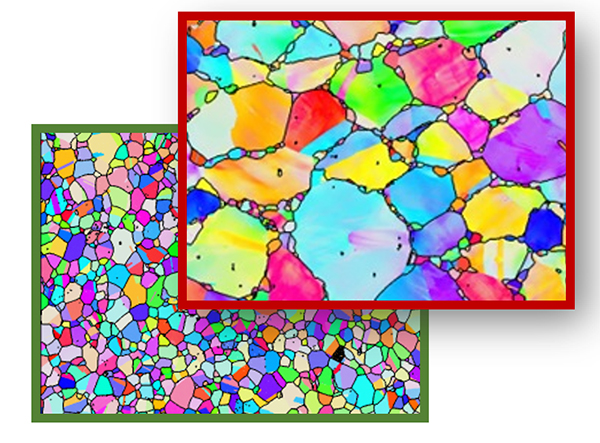

The requirements in terms of mechanical properties for materials used at harsh environments at extreme temperatures are constantly increasing in a wide range of sectors that embrace continuous innovation. Superalloys, which can have optimal mechanical properties up to temperatures around 700°C, provide a good solution to this problem. The SY286® iron-based superalloy is a grade of the A-286 alloy developed by Aperam for use in special screw applications. Aperam supplies its customers with SY286® products which have undergone solution treatment to provide good formability for the subsequent deformation steps. However, it has been observed for this grade that solution treatment can lead to a heterogeneous grain size distribution, with some grains considerably larger than the target average grain size. Such a microstructure is prohibitive, as it leads to severe degradation of the material’s properties in-service conditions. Grain growth is controlled and limited by the presence of second-phase particles, which hinder and block grain boundary migration by the Smith-Zener pinning phenomenon, hence a non-uniform distribution of second-phase particles can trigger the mechanism of abnormal grain growth. In some cases, microstructures contain stored energy, mainly in the form of dislocations induced by plastic deformation, which provides a driving force for grain boundary migration in addition to capillary forces. If the net driving force exceeds the anchoring force, grains can grow beyond the size limit predicted by the Smith-Zener model. Consequently, several hot-deformed microstructures were characterized by optical microscopy, SEM and EBSD to determine the influence of the initial microstructure and thermomechanical conditions -nominal and local, as estimated by finite element simulations- on the microstructural evolution of A-286 in the static regime. An analysis of the critical value and distribution of the stored energy required to trigger the critical grain growth mechanism was carried out by means of full-field microstructural evolution simulations (based on a 2D Level-Set numerical model integrated into a finite element environment) and by studying the effect of a stored energy gradient by means of cold indentation tests followed by a heat treatment. This work aims to provide a better understanding of the microstructure of Fe-Ni alloys, helping the industrial partner to optimize the manufacturing process of A-286 wires and bars, by controlling static microstructural evolutions to respect the targeted grain size and avoid the development of heterogeneous microstructures.

Keywords: Recrystallization, Grain growth, Stored energy, EBSD, Thermomechanical tests, Smith-Zener pinning