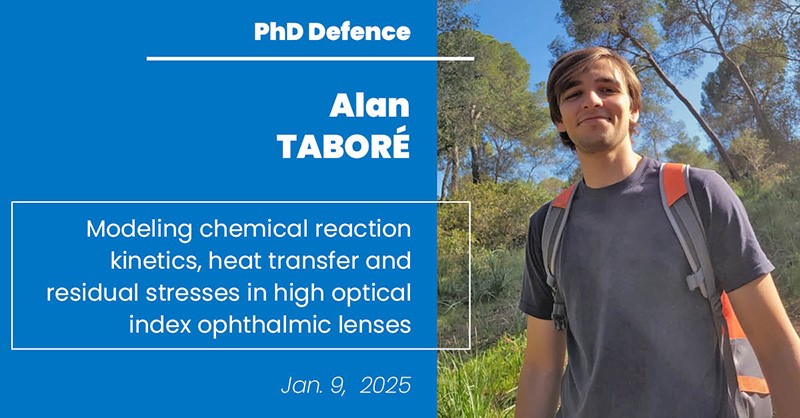

PhD defence of Alan Taboré

Modeling chemical reaction kinetics, heat transfer and residual stresses in high optical index ophthalmic lenses

Alan Taboré conducted his doctoral research in the the research teams, CFL and S&P under the supervision of Franck Pigeonneau and Jean-Luc Bouvard. He defends his PhD in Computational Mechanics and Materials specialty on Jan. 9th, 2025 in front of the following jury:

M. Steven LE CORRE Laboratoire de Thermique et Énergie de Nantes

Mme Jannick DUCHET-RUMEAU INSA de Lyon

Mme Valérie NASSIET ENI de Tarbes

M. Nicolas SBIRRAZZUOLI Université Côte d’Azur

M. Jean-Luc BOUVARD Mines Paris PSL (CEMEF)

M. Franck PIGEONNEAU Mines Paris PSL (CEMEF)

Abstract:

This thesis, in collaboration with EssilorLuxottica, aims to model the chemical reaction kinetics and stress evolution during the production of ophthalmic lenses.

This is a two-stage production process with an initial polymerization stage in a mold. During this stage, the resin solidifies and contracts, generating residual stresses. In the second stage, the lens is annealed to eliminate the stresses created by the polymerization process.

In the first instance, the cross-linking kinetics of thermosetting resins obtained by DSC are analyzed and then modeled using a Kamal and Sourour model coupled with a vitrification model. Subsequently, curing simulations coupling the solution of the chemical kinetics equation and the heat equation are implemented to study the influence of EssilorLuxottica’s process parameters and the chemical kinetics model on the temperature evolution during this stage of ophthalmic lens production. After studying the polymerization process, the next step is the annealing process. The thermomechanical behavior of the solid resin is studied using dilatometry, dynamic mechanical analysis, and photoelastic techniques. These results are then used to model the viscoelastic behavior of the resin. Finally, annealing simulations are performed to understand the effect of annealing process parameters on the final stress level in the lens.

The present study provides a good basis for optimizing the production of ophthalmic lenses. The development of tools and methods will facilitate the optimization of similar materials and processes. However, fluid/mechanical modeling during polymerization and additional experimental validation tests are still lacking. Regarding the annealing cycle, thermal optimization of the cycle through simulation could now be considered but the consideration of relaxation phenomena is to be improved.

Keywords: polymer, stress, lens, kinetics, thermoset, DSC