Open PhD position: Tribological modeling of stainless steel cold strip rolling.

CEMEF PhD thesis: Tribological modeling of stainless steel cold strip rolling

Global objective of work

Context

Detailed presentation

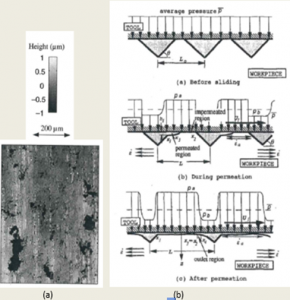

Cold rolling must reduce strip thickness, but also improve its mechanical properties and control its surface aspect. For stainless steels, the process starts from a very rough, shot-blasted and etched surface, whereas a mirror-like aspect must be reached in the end. This implies closing the deep shot-blast craters (Fig. 1a [1]). The latter are reservoirs for the lubricant, the pressurization of which opposes smoothening. Expelling oil from craters and closing them belongs to the lubrication mechanism called “micro-plasto-hydrodynamic” (Fig. 1b [2]).

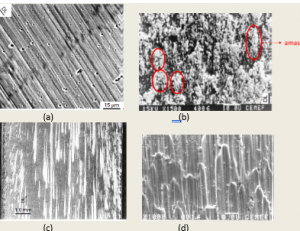

If the contact temperature increases too much, an adhesive transfer layer forms on the rolls. It then ploughs the strip surface (Fig. 2) and increases friction considerably [3]. The resulting damage may cause gloss-degrading microcracks in the end.

The proposed work is at the crossroad of strip-roll system thermal transfer, metal-metal adhesion in lubricated contacts, superficial material damage and modeling in tribology. The practical goal for Aperam is to equip its pass scheduling mechanical model of rolling with a capacity to predict these phenomena in order to determine schedules of both high productivity and low strip surface damage. The work program includes:

1) a thermal model of the strip – roll coupled system using the Finite Difference Method (FDM), knowing that strip plastic deformation is the main heat source friction, the contact surface friction a secondary but important one and that thermal transfer occurs under a high Péclet number, i.e. dominant advection.

2) implementation of a lubricant film thickness model based on Reynolds equation. The Lo & Wilson model [2] will be exploited for the first passes until crater are closed, a more standard form for the final passes [4].

3) on the basis of the lubricant film thickness, of surface temperature and of a simple superficial material damage model, adhesive transfer will be analyzed as in [5], in terms of its occurrence as well as the resulting roll roughness. The latter will be used in relevant tribological models of friction between rough surfaces [6], to determine boundary friction whenever critical conditions are met for the formation of the adhesive transfer layer.

4) This set of models and their conclusions will be checked by laboratory tribometry, by pilot rolling mill experiments under carefully monitored thermal conditions, as well as by plant production data analysis.

Figure 1 : cold rolling of stainless steel strip : plasto-hydrodynamic mechanism of elimination of large-scale roughness in the first passes. (a) 3D roughness measurement of a strip in the course of the rolling schedule, with craters partially closed [1] ; (b) modeling the plasto-hydrodynamic mechanism [2].

Figure 2 : illustration of the adhesive transfer mechanism [3]. (a) roll surface just after fine grinding ; (b) the same roll covered with a thick and rough adhesive transfer layer after rolling stainless steel ; (c) macroscopic aspect of the strip surface ploughed by the rough adhesive transfer layer: « comets » ; (d) ploughed zone at higher magnification : « shingles ».

References:

[1] M.P.F. Sutcliffe, F. Georgiades: Characterisation of pit geometry in cold-rolled stainless steel strip. Wear 253 (2002) 963-974

[2] S.W. Lo, W.R.D. Wilson: A theoretical model of micro-pool lubrication in metal forming. J. Trib. (Trans. ASME) 121 (1999) 731-738

[3] P. Montmitonnet, E. Felder: Usure, transfert et conséquences. De l'observation à la modélisation. Les Techniques de l'Ingénieur, TRI 504 (2017)

[4] N. Marsault, P.Montmitonnet, P. Deneuville, P. Gratacos: Un modèle de laminage lubrifié en régime mixte. Revue de Métallurgie - Science et Génie des Matériaux 98, 5 (Mai 2001) 423-433

[5] O. Filali : Approche multiphysique du contact frottant en grande déformation plastique : prédiction numérique du grippage d’alliages d’aluminium en mise en forme à froid. Thèse, UPHF (2020)

[6] W.R.D. Wilson: Friction models for metal forming in the boundary lubrication regime. J. Engg. Mat. Technol. (Trans. ASME) 113, 1 (1991) 60-68

Candidate profile and skills

Mechanics, Numerical modeling, Python language.

A first experience, theoretical or practical, in tribology and/or thermal transfer will be appreciated.

A motivation for experiments is necessary.

Rigor, dedication to a subject, aptitude to teamworking are important

Mastering of the English language is necessary (level B2 minimum)

General informations

- Industrial field: Mechanics and Materials

- Location:

- Mines Paris, CEMEF, Sophia Antipolis (80%)

- Aperam, Isbergues Research Centre (15%)

- Aperam, Gueugnon plant (5%) - Keywords: Cold rolling, tribology, numerical modeling, Thermal transfer, adhesion, lubricants and additives

- Cooperation: The PhD is funded by Aperam, a major stainless steel producer, under an ANRT CiFRE Grant. 2 other companies will fund 2 other PhDs on similar subjects. Collaboration and exchanges between the PhD students will be encouraged.

- Duration: 3 years

Contacts

- Team: Processes, Surfaces, Functionality group [PSF]

- Supervisors:

- Pierre Montmitonnet, Research Director (HDR), main supervisor.

- Imène Lahouij, Associate Professor, Mines Paris

- Frédéric Georgi, Research Engineer

To apply

- papers requiered to apply:

- your most recent CV

- Detailed, official proof of your grades during your most recent studies(maximum 3)

- One or more references from professors or heads of training programmes