Open PhD position: Tribological modeling of light alloy cold strip rolling.

CEMEF PhD thesis: Tribological modeling of light alloy cold strip rolling

Global objective of work

Contexte

Detailed presentation

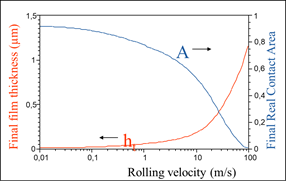

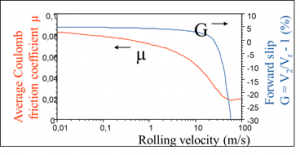

Cold rolling reduces strip thickness, improves its mechanical properties and controls its surface aspect. On the other hand, cold rolling is a process where tools (rolls) are the motor of the entrainment of the product, friction is therefore not allowed to be too low. To cope with these constraints, oils are chosen with a viscosity such that the interface works under the mixed lubrication regime. There is thus a hydrodynamic component, but also a chemical one, characteristic of boundary lubrication, their relative importance being proportional to the fractional real contact area.

The latter is a key output of a mixed lubrication regime model developed in the 1990s, coupled with a strip rolling model [1]. It determines the friction level (Fig. 1) but only through the “arbitrary” choice of a friction coefficient representing boundary contact zones. The objective of the present PhD is to eliminate this major limitation to the predictive character of the model.

Boundary friction depends critically on temperature since lubricant additives in Al cold rolling are of the polar kind, such as fatty alcohols and acids, which desorb beyond a critical temperature. This phenomenon is the main limitation of the reduction x velocity productivity factor. A boundary friction model must therefore include an efficient and precise mapping of temperature in the vicinity of the interface, on the strip as well as the roll sides.

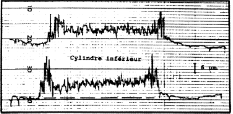

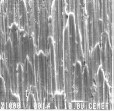

Temperature growth and desorption of additives is on the other hand the triggering factor, for part of the light alloys, of adhesive transfer [2] which forms a thick layer of uncontrolled roughness on the rolls (Fig. 2), in turn inducing a major drift of friction which forbids stable rolling.

Interface temperature must be carefully controlled. A known solution is to use oil in water (O/W) emulsions as lubricants, as is done on certain light alloy rolling mills. It decreases temperature but also brings an oil starvation effect. It can help controlling the hydrodynamic component and improve surface aspect in certain cases, but it may alternatively drift towards under-lubrication in others. It is important to understand these effects to manipulate them adequately [3,4].

The proposed work is at the crossroad of strip-roll system thermal transfer, metal-metal adhesion in lubricated contacts, lubrication theory and modeling in tribology. The practical goal for Constellium is to impart a better predictive capacity to its existing lubricated rolling model by importing those phenomena which condition friction values in boundary areas. The work program includes:

1) a thermal model of the strip – roll coupled system using the Finite Difference Method (FDM), knowing that strip plastic deformation is the main heat source friction, the contact surface friction a secondary but important one and that thermal transfer occurs under a high Péclet number, i.e. dominant advection. A particular attention will be devoted to validation thanks to laboratory pilot rolling mill experiments.

2) revisiting the lubrication model, its equations and workflow, for a better robustness and efficiency.

3) on the basis of the lubricant film thickness, of surface temperature and of a simple superficial material damage model, adhesive transfer will be analyzed as in [5], in terms of occurrence as well as resulting roughness. The latter will be used in relevant tribological models of friction between rough surfaces, to determine boundary friction whenever critical conditions are met for the formation of the adhesive transfer layer.

4) This set of models and their conclusions will be checked by laboratory tribometry, by pilot rolling mill experiments under carefully monitored thermal conditions, as well as by plant production data analysis.

Figure 1 : examples of results obtained by a coupled rolling – lubrication model: microscopic parameters on the left, macroscopic ones on the right (Stribeck ‘s curve and forward slip).

Figure 1 : examples of results obtained by a coupled rolling – lubrication model: microscopic parameters on the left, macroscopic ones on the right (Stribeck ‘s curve and forward slip).

Figure 2 - (a) adhesive transfer layer measured on a roll which has rolled an Al 5052 strip ; the central rough zone corresponds to the track of the rolled strip, 30 mm wide.

Figure 2 - (a) adhesive transfer layer measured on a roll which has rolled an Al 5052 strip ; the central rough zone corresponds to the track of the rolled strip, 30 mm wide.

Figure 2 - (b) consequence on the strip surface aspect : « shingles », resulting from ploughing of the surface by the peaks of the adhesive transfer layer.

Figure 2 - (b) consequence on the strip surface aspect : « shingles », resulting from ploughing of the surface by the peaks of the adhesive transfer layer.

References:

[1] N. Marsault, P.Montmitonnet, P. Deneuville, P. Gratacos: Un modèle de laminage lubrifié en régime mixte. Revue de Métallurgie - Science et Génie des Matériaux 98, 5 (Mai 2001) 423-433

[2] P. Montmitonnet, E. Felder: Usure, transfert et conséquences. De l'observation à la modélisation. Les Techniques de l'Ingénieur, TRI 504 (2017)

[3] W.R.D. Wilson, Y. Sakaguchi, S.R. Schmid: A mixed flow model for lubrication with emulsions. Tribology Trans. 37, 3 (1994) 543-551

[4] S. Cassarini: Modélisation du film lubrifiant dans la zone d’entrée pour la lubrification par émulsion en laminage à froid. Thèse de Doctorat en Sciences et Génie de Matériaux, Ecole des Mines de Paris (2007)

[5] O. Filali : Approche multiphysique du contact frottant en grande déformation plastique : prédiction numérique du grippage d’alliages d’aluminium en mise en forme à froid. Thèse, UPHF (2020)

[6] W.R.D. Wilson: Friction models for metal forming in the boundary lubrication regime. J. Engg. Mat. Technol. (Trans. ASME) 113, 1 (1991) 60-68

Candidate profile and skills

Mechanics, Numerical modeling, Python language.

A first experience, theoretical or practical, in tribology and/or thermal transfer will be appreciated.

A motivation for experiments is necessary.

Rigor, dedication to a subject, aptitude to teamworking are important

Mastering of the English language is necessary (level B2 minimum)

General informations

- Industrial field: Mechanics and Materials

- Location:

- Mines Paris, CEMEF, Sophia Antipolis (80%)

- Constellium C-TEC, Voreppe (20%) - Keywords: Cold rolling, tribology, numerical modeling, Thermal transfer, adhesion, lubricants and additives.

- Cooperation: The PhD is funded by Constellium, a major light alloy producer, under an ANRT CiFRE Grant. 2 other companies will fund 2 other PhDs on similar subjects. Collaboration and exchanges between the PhD students will be encouraged.

- Duration: 3 years (start: april 2023)

Contacts

- Team: Processes, Surfaces, Functionality group [PSF]

- Supervisors:

- Pierre Montmitonnet, Research Director (HDR), principal superviser.

- Imène Lahouij, Associate Professor, Mines Paris

- Frédéric Georgi, Research Engineer

To apply

- papers requiered to apply:

- your most recent CV

- Detailed, official proof of your grades during your most recent studies(maximum 3)

- One or more references from professors or heads of training programmes