Open PhD position: Thermal and tribological modelling of tube pilgering.

CEMEF PhD thesis: Thermal and tribological modelling of tube pilgering

Global objective of work

Context

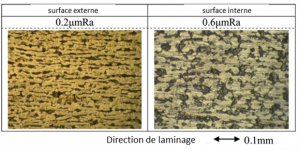

An important criterion is surface quality: no microcracks, moderate roughness. These characteristics depend on tool design and the strain path they impose on the one hand, secondly on the mechanical response of the alloy (ductility, toughness) and finally on the friction in the process, both on the internal and external tube surfaces. The lubrication regime is conditioned by the poorly know contact temperature. Its prediction by modelling is therefore of primary importance; it must be founded on a clear understanding of the physical and chemical mechanisms taking place at the microscale.

Detailed presentation

The objective of the work is a qualitative jump in the richness of the process modelling, by including (1) a thermal and (2) a tribological model (lubrication and friction). The FEM simulation of this incremental process is very costly, this is why an approach founded on its cyclic nature has been developed [1]. This will be the framework of the developments. Thermal transfer during the process raises no particular difficulty but requires a precise assessment of the tool temperatures, which is governed by their contact with the heat source, i.e. the plastic deformation of the tube. We will use an accelerated modelling of tool temperature, implemented in Forge Nxt [2]. These features constitute an original modelling framework on a quasi-unexplored subject.

Thanks to this improved modelling, the temperature-dependence of the stress-strain curves of certain Zr alloys will be accounted for. This might have consequences even in the cold forming domain, for which real deformation temperatures are poorly known. Moreover, internal and external contact temperatures determine lubricant effective viscosity, therefore lubricant film thickness [3]. They also impact wetting and adsorption capacity of lubricant components, hence its boundary properties. If contact temperature drifts, the lubricant loses efficiency and an adhesive transfer layer may form locally on tools, specially on the mandrel. Such a defect appears on pilgering mill as crises. Its roughness ploughs the tube surface and may dramatically increase friction [4].

Finally, internal as well as external friction modifies stress fields. The principle of the process is such that the tube metal undergoes alternate tension and compression stresses. Depending on alloy properties, this may lead to low-cycle fatigue which manifests through superficial microcracks of varying shapes; they must be shallow enough to be erased by chemical etching, otherwise the tube is rebutted. High friction, or a high internal / external friction difference, increases risks.

The work program is therefore at the crossroad of thermal transfer modelling in the mandrel/tube/die system, metal-metal adhesion in lubricated contact, near-surfaces mechanical damage study and modelling in tribology. Following [5] who proposes necessary modelling bricks for the prediction of seizure phenomena and their consequences, we will investigate the following points:

1) thermo-mechanical modelling: the cyclic process modelling of [1] will be complemented with cyclic thermal modelling of the mandrel/tube/ die system according to [2]: tube plastic deformation is the heat source, the sinks are cold tools where they are in contact with the tube and the lubricant jets elsewhere. The cyclic tool temperature model in [2] consists in extracting the heat source from the mechanical computation all along a cycle and applying it N times to the tools until they reach a permanent state.

For the validation of the simulation, pilgering tests with temperature measurement will be carried out. Preferably continuous monitoring by thermocouples will be achieved, or else just a maximum temperature assessment if the former proves impractical.

2) implementation of a Reynolds-equation-based lubricant film thickness model, starting from the purely hydrodynamic model of [3]. Strictly speaking it is invalid since reality is in the mixed lubrication regime (see figure 3), but an estimate of the real contact area will be derived and used as the basis for local friction estimation.

The lubricant is either an oil, or an emulsion, depending on the pilgering mill. In the latter case, an oil starvation model will be implemented, following [6].

Validation will be based on interrupted pilgering tests. Lubricant film thickness will be measured, together with the roughness at several positions along the deformation zone.

3) on the basis of the lubricant film thickness, of the surface temperature and of a near-surface damage model, adhesive transfer will be detected and modelled as suggested in [7], its roughness estimated. These predictions will be compared with mandrel roughness measurements. Using rough surface friction models such as [8], this will serve as an input for an estimate of boundary friction during “sticking crises” to be compared with friction observed during “normal operation”.

All these models and their conclusions will be validated using pilgering tests with temperature measurement, analyses of production monitoring and also more analytical laboratory experiments.

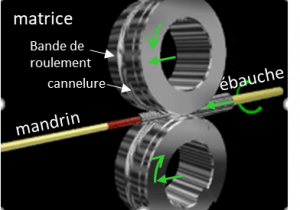

Figure 1: principle of tube pilgering. Arrows show movements: advance of the tube, mandrel + tube rotation, rolling without sliding of dies along the deformation zone (in red) of the mandrel.

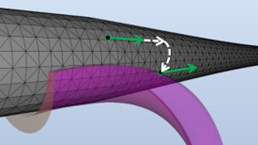

Figure 2 : FEM modelling of tube pilgering using Forge Nxt. The prior estimation of the transition geometry and the post-processing on pseudo-periodic data allows the reconstruction of particles deformation paths.

Figure 3: the prevailing lubrication regime leads to a higher roughness of the internal surface, as a thicker lubricant film protects asperities against flattening [3].

References:

[1] B. Lodej, K. Niang, P. Montmitonnet, J.-L. Aubin : Accelerated 3D FEM computation of the mechanical history of the metal deformation in cold pilgering of tubes. J. Mater. Process. Technol. 177 (2006) 188-191

[2] M.P. Miles, L. Fourment, J.L. Chenot: Finite Element calculation of thermal coupling between workpiece and tools in forging. Eng. Comput. 12, 8 (1995) 687-705

[3] H. Abe, T. Nomura, Y. Kubota: Lubrication of tube in cold pilgering. J. Mat. Proc. Technol. 214 (2014) 1627-1637

[4] P. Montmitonnet, E. Felder: Usure, transfert et conséquences. De l'observation à la modélisation. Les Techniques de l'Ingénieur, TRI 504 (2017)

[5] O. Filali : Approche multiphysique du contact frottant en grande déformation plastique : prédiction numérique du grippage d’alliages d’aluminium en mise en forme à froid. PhD Thesis, UPHF (2020)

[6] P. Montmitonnet, A. Stéphany, S. Cassarini, J.-P. Ponthot, M. Laugier, N. Legrand: Modelling of metal forming lubrication by O/W emulsions. Proc. ICTMP 2007 (Int. Conf. Tribology in Manufacturing Processes, Yokohama, 24-26 Sept. 2007), pp.85-90. A. Azushima, ed.

[7] P. Montmitonnet, E. Felder: A Third-Body Modelling Strategy for the Prediction of Adhesive Transfer Layer Formation on Forming Tools. Proc. ICTMP 2016 (Phuket, Thailand, 29 Feb – 2 March 2016), Thai Tribology Association, 2016, pp. 62-73

[8] W.R.D. Wilson: Friction models for metal forming in the boundary lubrication regime. J. Engg. Mat. Technol. (Trans. ASME) 113, 1 (1991) 60-68

Candidate profile and skills

Mechanics, Numerical modeling, Python language.

A first experience, theoretical or practical, in tribology and/or thermal transfer will be appreciated.

A motivation for experiments is necessary.

Rigor, dedication to a subject, aptitude to teamworking are important

Mastering of the English language is necessary (level B2 minimum)

General informations

- Industrial field: Mechanics and Materials

- Location:

- Mines Paris, CEMEF, Sophia Antipolis (80%)

- FRAMATOME, Paimboeuf plant (15%)

- FRAMATOME, Ugine Research Centre (5%) - Keywords: Cold tube pilgering, tribology, numerical modeling, Thermal transfer, adhesion, lubricants and additives

- Cooperation:The PhD is funded by FRAMATOME, under an ANRT CiFRE Grant. 2 other companies will fund 2 other PhDs on similar subjects. Collaboration and exchanges between the PhD students will be encouraged.< /li>

- Duration: 3 years

Contacts

- Team: Computational Solid Mechanics [CSM] and Processes, Surfaces, Functionality group [PSF]

- Supervisors:

- Katia Mocellin, Research Director (HDR), main supervisor

- Pierre Montmitonnet, Research Director (HDR), co-supervisor

- Imène Lahouij, Associate Professor, Mines Paris

- Frédéric Georgi, Research Engineer

To apply

- papers requiered to apply:

- your most recent CV

- Detailed, official proof of your grades during your most recent studies(maximum 3)

- One or more references from professors or heads of training programmes