Open PhD position: Gluing optimization of a heterogeneous interface with electrical contact recovery using conductive particles

CIFRE 2021 PhD THESIS: Gluing Optimization of a heterogeneous interface with electrical contact recovery using conductive pArticLes

Global objective of work

Optimization of an adhesive formulation filled with conductive particles and of the assembly process parameters, to guarantee the long-term electrical contact recovery for acoustic transducers used in ultrasound probes for the healthcare sector.

Context

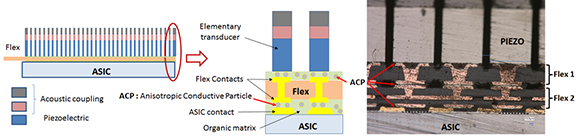

GE Healthcare - Parallel Design SAS designs and develops medical ultrasound probes. Manufacturing of a probe requires the assembly of various materials using specific adhesives filled with conductive particles which insure the electrical contact between an ultrasound transducer and a flexible organic substrate. A good distribution of particles during the bonding process and conservation of the electrical contacts during polymerization will guarantee thermal, acoustic and mechanical performances of the probe during its lifetime.

Detailed presentation

The objective of the thesis is to study the influence of the filler ratio, particle size, particle geometry on an identified particle technology (polymer beads with conductive surface) and the viscosity of the organic matrix according to its formulation, on the final performance of the assembly (electrical contacts, mechanical properties, adhesion and electro-acoustic performance of the transducer). The assembly conditions and parameters (pressure, speed, and assembly geometries) will also be studied.

Rheological characterization of polymer matrices with or without fillers will be carried out to evaluate fluid-particle coupling and identify behavioral laws during glue spread-out. This matrix-particle coupling will also be evaluated by mechanical tests.

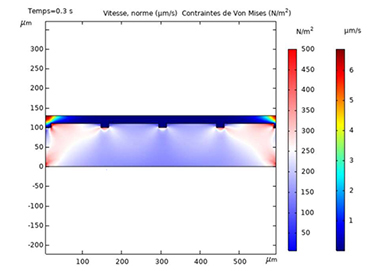

The influence of the processing conditions on the adhesive flow will constitute the second part of the experimental study, which will be associated with a numerical study of the process in order to optimize it.

In addition to the macroscopic scale study, the contact of an elementary particle will be analyzed in order to evaluate if the mechanical and electrical behaviors of the assembly at a local scale can be transposed to global scale.

In parallel with experimental studies, a numerical study will be conducted to reproduce glue and particles flows. Modelling will primarily be carried out using Comsol Multiphysics software. Other calculation codes will be evaluated if the existing fluid-particle behavioral laws do not converge or if the simulations on model geometries do not fit with experimental observations. This numerical study of the particle distribution will then be coupled with statistical models to evaluate the probability of faults (short circuit, open circuit, local lack of glue, etc.) in correlation with experimental data.

The behavioral laws identified will then be evaluated on more complex geometries, representative of a real assembly, to verify whether the numerical tools implemented lead to a significant reduction of development lead-time for designing the optimal gluing zone versus surface topography, type of organic matrix or particles.

The first semester will be devoted to assembly processes as well as analysis or characterization techniques and to a bibliographical report on:

- low temperature assembly techniques (≤ 120 °C) with contact recovery, the typology of conductive particles and models of electrical contacts,

- formulation and chemistry of organic matrices used as glues, in relationship with cross-linking kinetics and rheology,

- the reliability of the joint obtained submitted to various external constraints: thermal, humidity, chemical (sterilization).

Candidate profile and skills

- Engineer or master's degree in science/chemistry/material engineering/ microelectronics

- Taste for experimental work, analysis and characterization techniques

- Notions in numerical simulation

- Mastery of the English language

- Important autonomy, ease of regular communication with several interlocutors.

General informations

- Industrial field: Mechanics and Materials

- Location:Sophia-Antipolis:

- CEMEF MINES ParisTech

- GE Healthcare Parallel Design SAS - Keywords: Gluing, adhesion, electrical contact recovery, rheology, wetting, particles, flow.

- Cooperation: The doctoral student will be a GE Healthcare employee, CIFRE thesis. The PhD student will be present 50% of the time at Parallel Design in Sophia-Antipolis and 50% in the CEMEF laboratory, located 5 km from each other, which is an advantage for a close collaboration. Working meetings will be set regularly between the partners, at least every two months.

- Duration: 3 years

- Gross annual salary: CIFRE GE Healthcare remuneration: 30k€

Contacts

- Team: Surfaces and Processes [PSP]

- Supervisors: Pr. Karim Inal and Dr. Frédéric Georgi

To apply

- papers requiered to apply:

- your most recent CV

- Detailed, official proof of your grades during your most recent studies(maximum 3)

- One or more references from professors or heads of training programmes